What needs to be prepared before manufacturing ATVs(All-Terrain Vehicles)?

Manufacturing All-Terrain Vehicles (ATVs) is a complex systems engineering project. Before the production line can even start, comprehensive and meticulous preparatory work is essential. These preparations form the foundation for successful mass production and can be divided into several core levels:

Phase 1: Strategic and Planning Preparation

This is the “theoretical planning” stage, which defines what to produce and why.

- Market Research and Product Definition:

- Market Demand: Where is the target market (North America, Europe, Asia)? What are user preferences (sport, utility, youth models)? What are competitors’ products and prices?

- Product Positioning: Decide on the type, displacement, and configuration of ATV to produce (e.g., 300cc Sport, 500cc 4×4 Utility).

- Regulations and Standards: Conduct in-depth research into the mandatory regulations of the target market, such as the US EPA (Emissions), CARB (California Emissions), DOT (Safety) standards, or the EU’s CE certification. This is the non-negotiable baseline for market entry.

- Business Plan and Budgeting:

- Financial Assessment: Estimate R&D investment, production line setup costs, raw material procurement, labor costs, etc., and forecast the return on investment.

- Capacity Planning: Determine initial and long-term annual production targets.

Phase 2: Technical and R&D Preparation

This is the stage of turning an idea into producible blueprints—the “soul” of the product.

- Research and Development (R&D):

- Concept Design: Create exterior styling and define the overall layout.

- Engineering Design: This is the core. It includes:

- Structural Design: Use CAD software for 3D modeling and FEA (Finite Element Analysis) of the frame and suspension system to ensure strength and rigidity.

- Powertrain Matching: Select the appropriate engine, transmission, and drivetrain, and conduct simulation tests.

- Electrical System Design: Design the full wiring harness, ECU, instrument cluster, etc.

- Prototype Manufacturing and Testing:

- Build a few fully functional prototype units.

- Conduct rigorous durability, performance, safety, and environmental (high/low temperature, water spray) tests.

- Iteratively modify the design based on test results until the product fully meets all standards.

- Technical Documentation and Production Process Planning:

- Create the BOM: Develop a detailed Bill of Materials, listing all parts, specifications, and quantities required to produce one vehicle.

- Define Process Documentation: Plan the machining path for each part and the assembly steps for each station.

- Design Molds and Jigs/Fixtures: Develop injection molds for plastic covers (like fenders, body panels) and design specialized jigs for welding and assembly to ensure product consistency.

Phase 3: Supply Chain and Procurement Preparation

This is the stage of gathering the necessary “provisions” for production.

- Supplier Sourcing and Assessment:

- Find potential component suppliers (for engines, shock absorbers, tires, instruments, wiring harnesses, etc.) based on the BOM.

- Audit suppliers to evaluate their quality systems, production capacity, and cost.

- Key Strategy: For core components (e.g., engine, ECU), it is common to choose reliable, established brands or set up in-house production lines.

- Procurement and Supply Chain Management:

- Sign contracts with selected suppliers, finalizing prices, delivery lead times, and minimum order quantities.

- Establish stable channels for raw materials and component supply to prevent production disruptions.

- Set up Incoming Quality Control (IQC) standards and procedures.

Phase 4: Production Facility and Personnel Preparation

This is the stage of building the “battlefield” and training the “troops.”

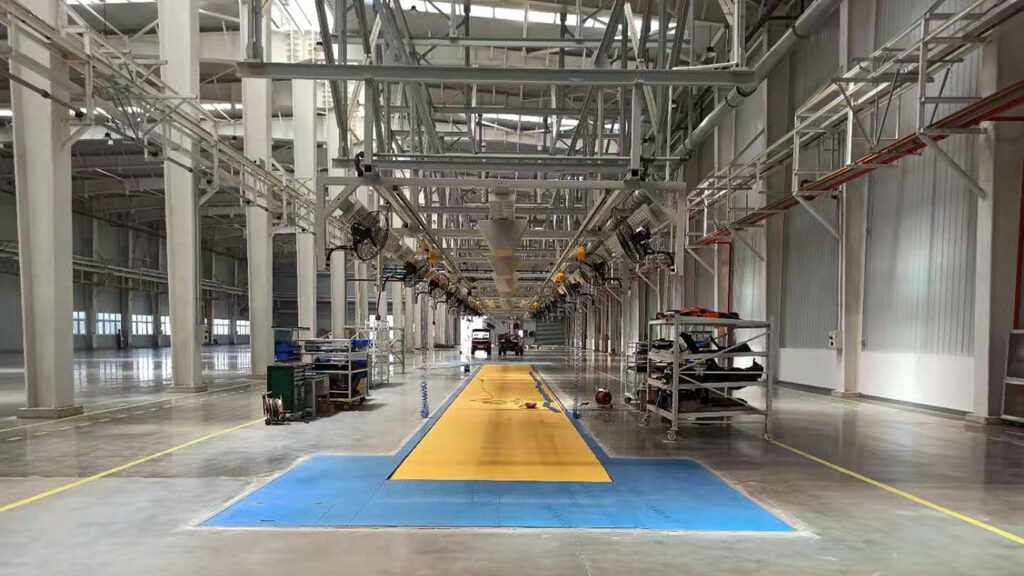

- Production Line Construction and Layout:

- Plan and construct the various workshops mentioned earlier: cutting/welding, painting, assembly, inspection, etc.

- Procure, install, and calibrate production equipment (laser cutters, welding robots, painting lines, conveyors, filling machines, etc.).

- Team Building and Training:

- Assemble teams for management, R&D, quality, production, procurement, and sales.

- Provide systematic training for production line workers on operations, safety, and quality awareness.

Phase 5: Quality and Certification Preparation

This is the stage that ensures the product can be sold legally and gain market trust.

- Establish a Quality Management System:

- Implement a Quality Management System, such as ISO 9001, to ensure full-process quality control from incoming materials to finished product shipment.

- Product Certification:

- Send final production prototypes to accredited laboratories in the target countries for testing to obtain necessary certifications (e.g., EPA, CE). This is the “market access pass” for the product.

In summary, manufacturing ATVs requires preparing a complete “ecosystem.” It is not simply about buying parts and assembling them. It requires comprehensive planning across market strategy, product design, supply chain, manufacturing, and quality certification. Only with thorough preparation in all these areas can one efficiently manufacture qualified ATVs that are competitive in the marketplace.