What are the characteristics of a CKD automotive production line?—Car Production Line Design and Fabrication Factory

A CKD (Completely Knocked Down) automotive production line is a very specific and important mode of vehicle manufacturing. Its core characteristics can be summarized as: “Centered on parts assembly, combining flexibility and localization.”

It is distinctly different from traditional complete knock-down assembly or full localized production, and primarily exhibits the following key features:

1. Core Characteristic: Parts Assembly

- Definition: CKD stands for “Completely Knocked Down.” The automaker completely disassembles a vehicle into individual parts or sub-assemblies (such as body panels, engine, transmission, seats, instrument panel, etc.), packs them into “kits,” and ships them to a factory in the target country.

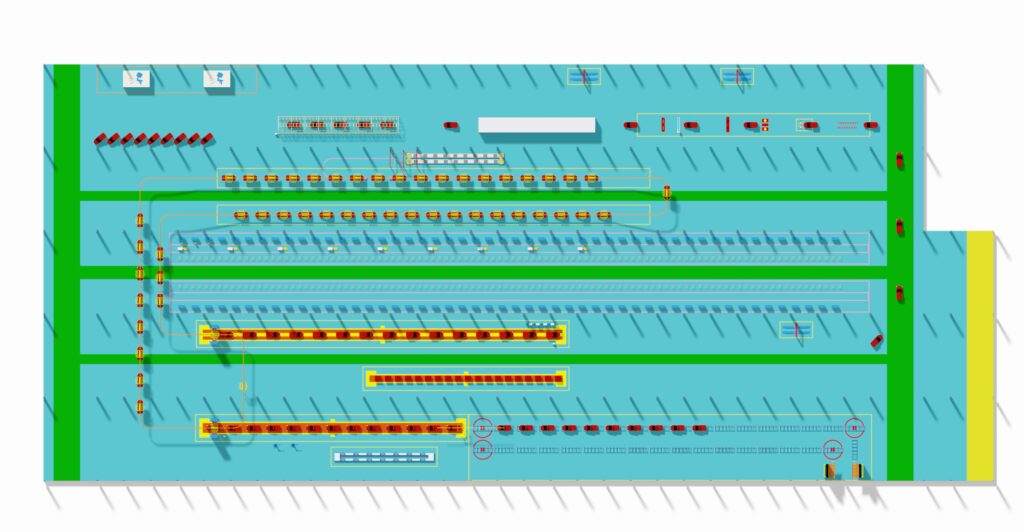

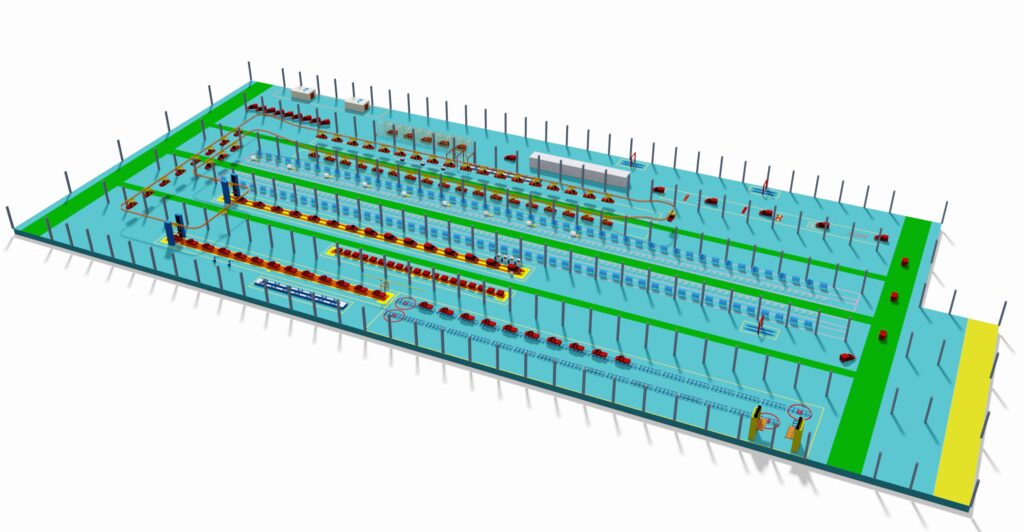

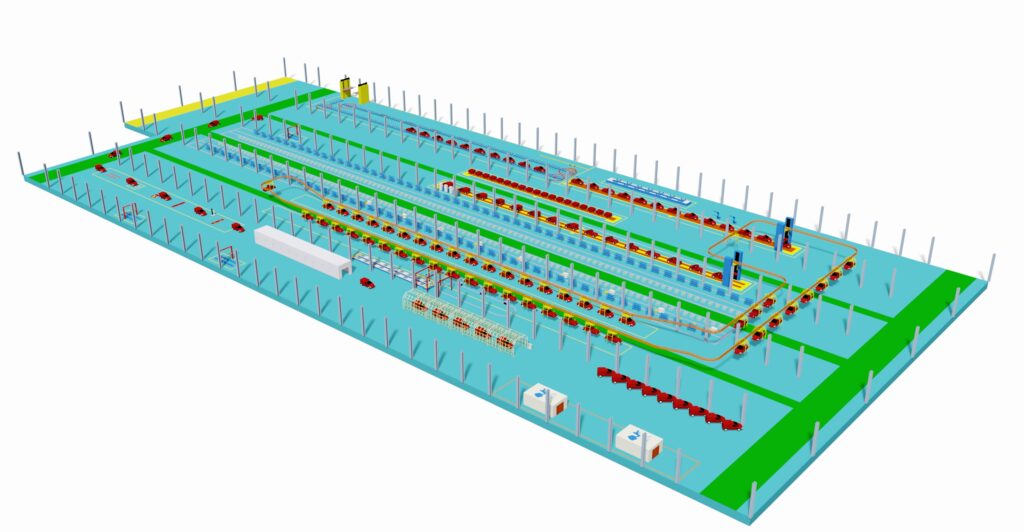

- Production Process: The task of the local factory is to assemble these parts, much like “building a large-scale model,” through welding, painting, and final assembly to create a complete vehicle. This differs from SKD (Semi-Knocked Down) or models that involve significant local part sourcing.

2. Core Driver: Bypassing Trade Barriers & Reducing Costs

- High Tariff Avoidance: Many countries impose much higher tariffs on imported complete vehicles than on imported auto parts to protect their domestic auto industry. Using the CKD model can significantly reduce tariff costs.

- Meeting Localization Requirements: Regulations in many countries require that vehicles sold domestically must contain a certain percentage of locally produced or procured parts. CKD is a common method to meet this requirement, allowing factories to gradually increase the proportion of locally sourced parts.

3. High Production Flexibility & Market Adaptability

- Low Initial Investment: Compared to building a full-process factory that includes stamping, engine block casting, etc., a CKD factory requires a much smaller investment and carries lower risk. It primarily needs welding, painting, and assembly lines.

- Rapid Market Response: For regions with small or unstable markets, building a full-process factory is not economical. The CKD model allows for quick establishment of production capacity to flexibly test and meet local market demand with small batches and multiple models.

- Facilitates Product Localization: It allows for easy adaptation of specific configurations for the local market, such as adjusting suspension for poor road conditions or adding specific cold/ hot climate packages.

4. Relatively Lower Technical Barrier, but Quality Control is Key

- Technology Transfer & Personnel Training: The CKD model is a way for the parent automaker to transfer production technology and management expertise overseas. Local workers and engineers can learn starting from basic assembly, gradually improving their skills.

- Challenge of Consistent Quality Control: Since core components are still produced by the parent factory, ensuring the quality of these parts and the assembly quality at the overseas factory matches the original standard is a major challenge. This requires strict quality control systems and frequent audits.

5. Complex Supply Chain Management

- Global Logistics Coordination: This involves managing the complex logistics of transporting thousands of parts from the source factory to the overseas plant, ensuring all parts arrive at the production line on time, in sequence, and intact. Any missing part can halt production.

- Inventory Management Pressure: To maintain uninterrupted production, CKD factories need to maintain high safety stock levels of parts, which ties up significant capital.

Summary

The essence of a CKD automotive production line is a strategic compromise and balance. It balances the automaker’s need for global expansion with the target country’s desire to protect its domestic industry and promote employment. For automakers, it is an effective tool to enter and establish roots in emerging markets with relatively controllable costs and risks. Therefore, the characteristics of a CKD production line are deeply marked by the dual genes of “globalization” and “localization.”