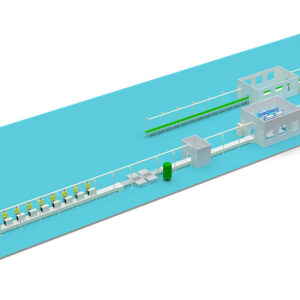

SKD Air Conditioner Assembly Line—Air Conditioner Assembly Line Manufacturer

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

SKD (Semi-Knocked Down) air-conditioner assembly line: we pre-build the units in China—indoor and outdoor sections pre-assembled, pipes brazed, refrigerant partly charged—then ship them as “half-finished” modules to the overseas plant. On site you only snap-fit a few quick couplings, evacuate, top up gas, test and pack. It cuts field labour by more than half and needs no skilled brazers, so it is perfect for markets that want “fast ramp-up, friendly duty, ordinary labour”.

Core highlights(for your reference)

– **Ready-to-fit**: after uncrating quick joints; mechanical hook-up finished fast.

– **High tempo**: one piece every 60–120 s, two-shift 24 h, 30–50 k sets per month easily.

– **Lower duty**: most countries treat SKD as “semi parts”, 10–20 percentage points lower than CBU.

– **Refrigerant flexible**: handles R32, R410A, R290; evacuation ≤ 20 Pa, ATEX & recovery built in.

– **Fool-proof**: each station has a scanner, program downloaded automatically, operator works by Andon, no model memorising.

Main stations (can be added or skipped)

1. Module unbox & cosmetic check

2. Indoor/outdoor snap-fit (no brazing)

3. Auto evacuate & refrigerant top-up

4. PCB scan-test

5. Performance run (cool/heat auto toggle)

6. Clean & label

7. Auto case-seal & robot palletise

In one sentence: **SKD air-conditioner line keeps the “hard brazing and vacuum” in China and leaves the “easy Lego job” overseas—plant speed like toy bricks, duty like parts, output like finished goods.**