Motorcycle Assembly Line Professional Design—Assembly Line Conveyor Factory—Our Clients’ Motorcycle Assembly Lines

Description

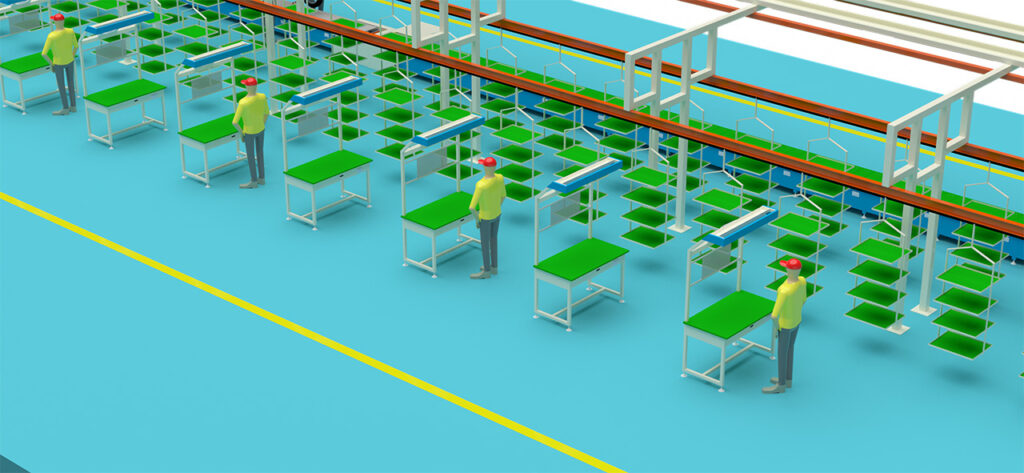

Motorcycle/E-bike Assembly Lines are Suitable to Assemble/Produce 2 wheel Motorcycles, 2 wheel Scooters, 2 wheel Electric-cycles, 2 wheel E-Bikes, Bicycles, and so on.

The main advantages for international clients purchasing motorcycle assembly lines from China are reflected in the following aspects, which together form a strong market competitiveness:

Cost-Effectiveness (The Core Attraction)

1. Significant Price Advantage:

Low Manufacturing Costs: China maintains a clear advantage in the costs of raw materials, components, energy, and labor, making the overall manufacturing cost of the production line much lower than in traditional industrial nations like Europe, America, and Japan.

Controllable Overall Project Cost: Chinese suppliers can provide more cost-effective turnkey solutions, from equipment procurement and technical design to installation and commissioning, helping clients start projects with a lower initial investment.

2. Optimized Return on Investment (ROI):

The lower upfront investment means clients can achieve a faster payback period and reduce investment risks, which is particularly suitable for investors in emerging markets or small and medium-sized motorcycle manufacturers with limited budgets.

Technology and Manufacturing Capability

3. Mature and Comprehensive Technology:

Technology Integration and Innovation: China’s equipment manufacturing industry has absorbed global advanced technologies and can innovate and optimize based on market demands. The production line technology is mature and reliable, meeting various production needs from basic to high-end.

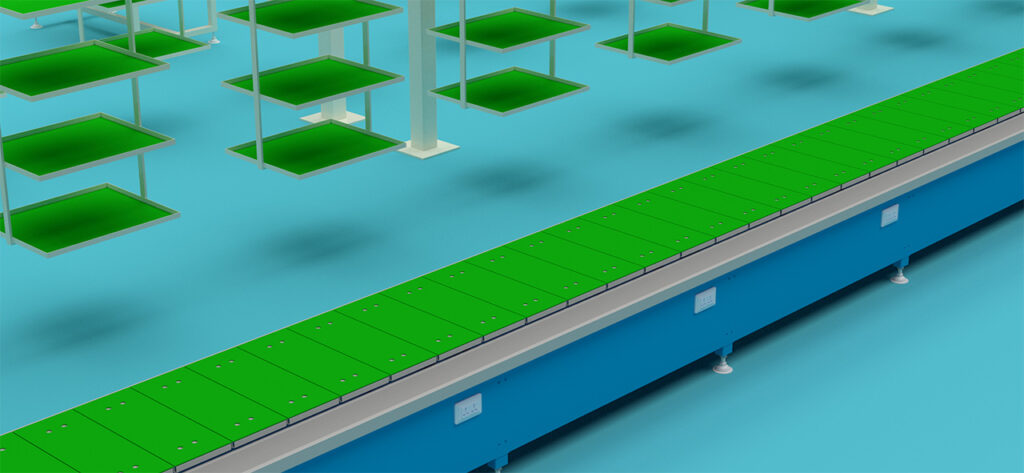

Modularity and Flexibility: Chinese suppliers can provide highly modular assembly lines, allowing clients to configure them flexibly according to their specific products (e.g., scooters, off-road bikes, three-wheelers) and capacity requirements, supporting future expansion or modification.

4. Strong Supply Chain and Manufacturing Ecosystem:

Complete Industrial System: China possesses the world’s most complete industrial spectrum. Nearly all components, sensors, and control systems required for the assembly line can be sourced domestically, ensuring collaborative efficiency and production stability.

Rapid Response and Delivery: A robust local supply chain means shorter procurement cycles for parts and faster manufacturing speeds, significantly reducing the overall lead time from order to delivery.

Customization and Service Advantages

5. High Customization Capability:

Chinese suppliers are highly adept at providing “tailor-made” solutions based on clients’ specific needs. Whether it’s production cycle time, level of automation (from semi-automatic to fully automatic), process flow, or integration with existing equipment, they can offer personalized solutions.

Ability to adapt to the special standards and regulatory requirements of different national markets (e.g., emission standards, safety regulations).

6. Comprehensive Turnkey Project & Service Support:

Most reputable Chinese suppliers offer “one-stop” services, from design and manufacturing to installation, commissioning, training, and after-sales support.

Professional Technical Training: They provide comprehensive training for the client’s operational, maintenance, and management staff to ensure the smooth commissioning and optimal performance of the production line.

Responsive After-Sales Service: They establish global service networks or partner with local service agencies to provide remote technical support, rapid spare parts supply, and on-site maintenance.

Market and Policy Advantages

7. Extensive Project Experience:

Chinese suppliers not only serve the domestic market but also have extensive experience exporting to markets worldwide, such as Southeast Asia, South Asia, Africa, and South America, giving them a deep understanding of the operational challenges and needs in different environments.