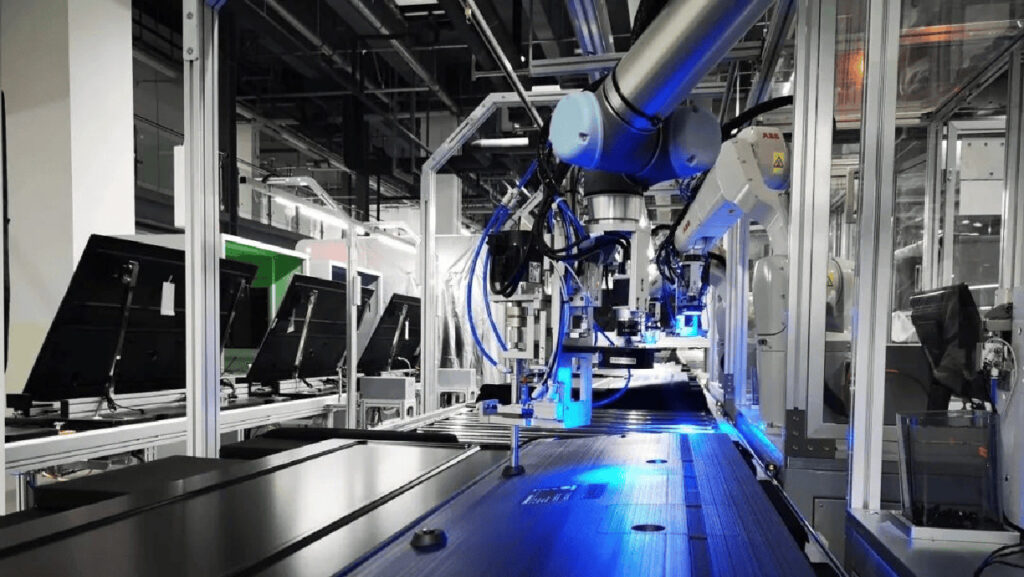

Intelligent Assembly Line Factory in China—Automated Television Assembly Line

Description

We are a professional manufacture of TV Assembly Line/TV Production Line solutions.

TV Assembly Lines/TV Production Lines are Suitable to Assemble/Produce following Televisions and TVs and so on.

Automated Television Assembly Line – Integrated Design Plan

The automated television assembly line represents the highest level of modern manufacturing, with the core objectives of achieving a production model characterized by high efficiency, high consistency, traceability, and low labor dependency.

Detailed Key Automation Modules

A highly automated television assembly line typically includes the following core modules:

1. Automated Logistics and Feeding System

AGVs/Material Handling Robots: Automatically transport materials (e.g., screen modules, chassis, mainboards) from the warehouse to designated line-side stations.

Automated Storage and Retrieval System (AS/RS): Interfaces with the AGV system for automated material storage/retrieval and information management.

Vision-Guided Robots: Use 6-axis robots combined with 2D/3D vision systems to accurately identify and pick parts from disorganized bins for feeding.

2. Automated Mechanical Assembly Cells

Robotic Dispensing Cell: Uses high-precision robots to apply sealant or adhesive along predefined paths onto the front bezel or screen frame, ensuring uniformity and no gaps.

Automatic Screwdriving Cell: Employs multi-spindle servo fastening systems to automatically feed, tighten, and record the torque and angle of every screw. Data is uploaded to the MES for traceability.

Precision Press-Fitting Cell: Uses servo presses to precisely press-fit the screen module into the front bezel and join the front and rear covers, controlling force and displacement to prevent damage and ensure tight bonding.

3. Automated Transfer and Positioning System

Friction Roller Conveyors/Belt Conveyors: Used for horizontal transfer.

Lift & Transfer Units/Shuttles: Used to transfer televisions between parallel lines or different process segments.

Precision Positioning Fixtures: Use servo-driven locating pins or clamps to ensure the TV is precisely secured at each station, providing a reference for robotic operations.

4. Automated Testing and Quality Inspection System

Online Power-On Test: When a TV arrives at the station, probes or connectors automatically engage to perform power-on and basic circuit tests.

Automated Vision Inspection System:

Screen Defect/Pixel Inspection: Uses high-resolution CCD cameras to automatically detect bright spots, dead pixels, color spots, and Mura (uneven brightness) under various solid-color screens.

Cosmetic Scratch Inspection: Detects scratches, dents, or stains on the chassis and bezels.

Component Assembly Verification: Checks if interfaces, buttons, indicator lights, etc., are properly assembled and not missing.

Automated Signal and Functional Testing:

Robotic arms automatically grasp and plug/unplug cables (e.g., HDMI, USB) and play test content.

Audio test systems use microphone arrays to capture and analyze speaker output, assessing sound quality and channels.

Wi-Fi/Bluetooth testing is performed by antennas within shielded boxes, automatically verifying wireless connection performance.

5. Automated Packaging System

Automatic Bagging Machine: Automatically places a protective bag over the TV screen.

Automatic Cartoning/Case Sealing Machine: Robots place the TV and accessories into the carton, automatically performing case sealing and labeling.

Robotic Palletizing: Industrial robots automatically and neatly palletize boxed televisions onto pallets according to predefined patterns.