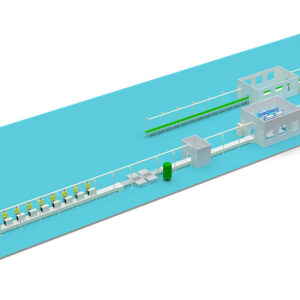

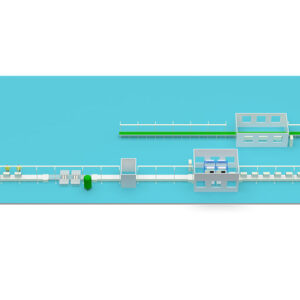

Home Air-Conditioner Indoor Unit Assembly Line—Automated Air Conditioner Assembly Line

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

Home Air-Conditioner Indoor Unit Assembly Line Reference Flow:

Loading

An operator lifts the wall-mounting plate, front frame, and base—each plastic part—off the rack, gives them a quick visual check, and hangs them one by one on the pallet. The synchronized belt then carries the pallet slowly forward.

Pre-fitting the air duct

The blower wheel is pressed gently onto the motor shaft until no play is felt. The complete motor-blower unit is then slid into the rubber grommets in the base and secured with hand-started screws.

Evaporator positioning

Both hands support the fin-and-tube coil, keeping fingers clear of the sharp fins, and the coil is lowered horizontally into the base slots. The temperature probe is pushed into the spring clip on the return bend so it sits flat against the copper.

Electrical box assembly

The main control board is slid along the rails of the plastic electrical box until the latch clicks. The whole box is then snapped onto the pillars of the base and fixed with hand-driven screws whose heads must stay flush with the plastic surface.

Wiring harness connection

Connectors are mated color-to-color: white to white, black to black. Each plug is pushed straight down by the root until a second click is heard; a gentle tug confirms it is locked. Excess cable is looped and tied with a nylon strap against the inner wall so the blower cannot touch it.

Installing the louvers

The blade shafts are aligned with the semi-circular notches in the front frame—one side first, then the other—so that all blades move together. A manual swing test must feel smooth and silent.

Closing the front frame

The frame is held with both hands, its locating pins guided into the key-hole slots of the base: lower edge first, upper edge pressed down afterward. The perimeter is patted evenly until every clip snaps home. Two tamper-proof screws are then driven and capped with rubber plugs for a clean look.

Foam and tape application

A continuous strip of anti-vibration foam is run along the joint between base and frame. Two layers of insulating tape are wrapped around the root of the evaporator pipes to prevent condensation drip.

Cosmetic cleaning

A lint roller is passed over the air outlet, and a lint-free cloth dampened with alcohol wipes the glossy surfaces of the frame. Any scratch or stain spotted at this point sends the unit off-line for rework.

On-line electrical test

After the barcode is scanned, the test rig powers the unit automatically. Indicator lamps light in sequence, the blower runs forward and reverse, and the louvers sweep. A “PASS” on the display releases the unit; power is then cut.

Vacuum and preliminary refrigerant charge

Quick-couplers connect the evaporator tubes to the vacuum pump. Once the target vacuum is reached, the system switches automatically to admit a small charge of refrigerant for the final assembly-line alignment.

Running check under commercial test

The indoor unit is moved to a mock-up room, connected to standard mains and a remote controller, and run in cooling mode. An operator listens for blower noise and feels the air temperature at the outlet. Any abnormal vibration or sound stops the test; otherwise the unit is powered down.

Nameplate and energy-label application

The self-adhesive nameplate is pressed into the recessed area on the base so all edges lie flat. The energy-efficiency label is then applied, its edges aligned with the nameplate; skew is not allowed.

Bagging and packing

A PE bag is slipped over the unit with its open end toward the rear. Top and bottom foam blocks are fitted, the carton is closed, and an operator runs wide tape along all seams, overlapping start and finish to leave a smooth, wrinkle-free joint.

Palletizing and warehouse entry

After an automatic weight check, the carton rides roller conveyors to the palletizer. The robot grips each box, rotates it, and sets it gently on the pallet. A sheet of cardboard is placed between layers until the stack is complete. A forklift takes the pallet away to the finished-goods warehouse, and the line cycle ends.