Air Conditioner Assembly Line Main Components—Air Conditioner Assembly Line Factory and Support

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

Air Conditioner Assembly Line Main Components

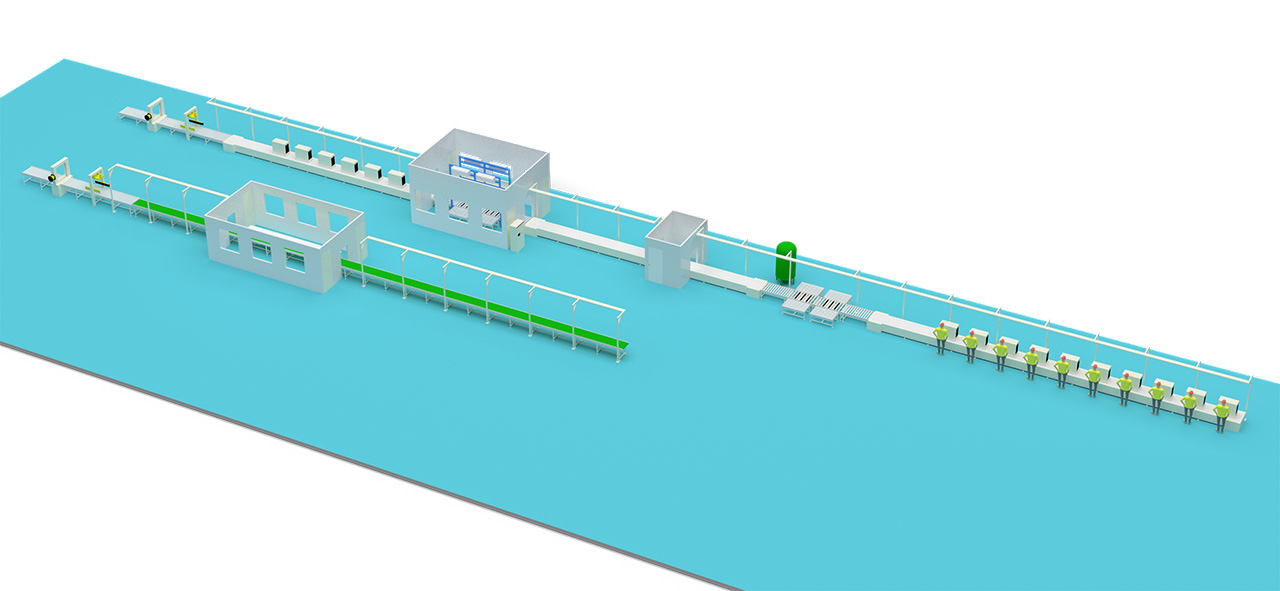

An air conditioner assembly line is a complex and precise system. It is typically divided into two main lines: the **indoor unit assembly line** and the **outdoor unit assembly line**, due to significant differences in their structure, components, and processes.

Main Components

A complete AC assembly line typically includes the following subsystems:

1. Conveyor System:

Types: Commonly uses slat chain conveyors (good load-bearing, suitable for heavier outdoor units), roller conveyors (for turns and connections), belt conveyors (for light-load areas), and non-powered roller conveyor (manually pushable, highly flexible).

Function: Serves as a moving work platform, carrying the product sequentially through each station.

2. Workstations:

Each station has customized workbenches, tools, material racks, and necessary utilities (power, air, network).

3. Automation & Testing Equipment:

Automation Equipment: Robots (e.g., for automatic screw driving, label application, handling), automatic refrigerant charging stations, automatic packing machines, etc.

Testing Equipment: Critical stations integrate testing equipment, such as leak detectors, electrical safety testers, performance test chambers, etc.

4. Material Distribution System:

Uses AGVs, tuggers, or manual forklifts to deliver components from the warehouse to line-side storage just-in-time, based on Kanban or system instructions.

5. Information Management System:

MES (Manufacturing Execution System): Tracks production progress, quality data, and material consumption in real-time for visual management.

Andon System: If a problem occurs (e.g., quality defect, material shortage), workers can press a button to trigger an audio-visual alarm, prompting rapid response from management.