Air Conditioner Assembly Line Characteristics—Chinese Air Conditioner Assembly Line Factory

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

Characteristics of Air Conditioner Assembly Lines

Air conditioner assembly lines have distinct features that blend general principles of major appliance manufacturing with the specific process requirements unique to AC products. Here is a detailed analysis of their core characteristics:

Core Characteristics of Air Conditioner Assembly Lines

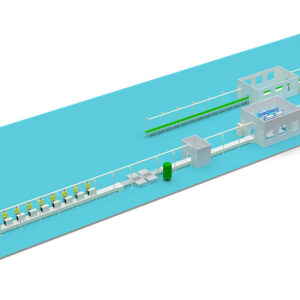

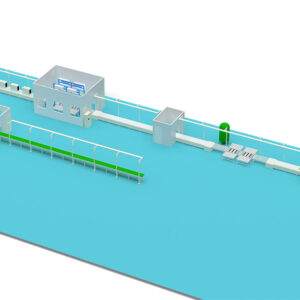

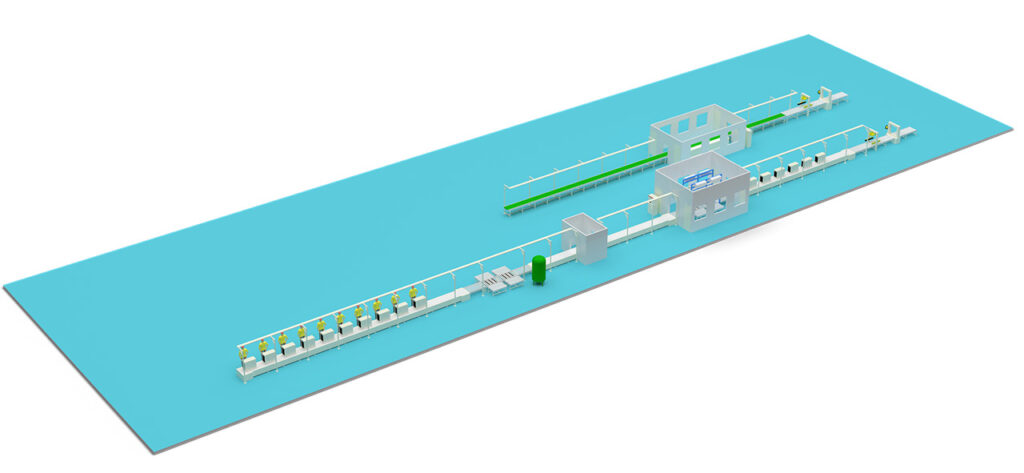

1. Two Parallel Lines Deeply Integrated with Modularization

This is the most distinctive feature of AC assembly.

Parallel Lines: Typically separated into indoor unit assembly lines and outdoor unit assembly lines. Since the structure, components, weight, and testing requirements for indoor and outdoor units are entirely different, separate lines significantly improve efficiency and specialization.

Deep Modularization: Both main lines rely heavily on highly modular sub-assemblies.

Outdoor Unit Sub-Assemblies: Include pre-assembly of the “two heat exchangers” (condenser, evaporator), electrical control box assembly, motor-fan assembly, compressor module, etc.

Indoor Unit Sub-Assemblies: Include scroll fan assembly, electrical control box, evaporator component, air deflector module, etc.

Advantage: Decomposes complex final assembly processes, shortens the cycle time of the main line, enables specialized production, facilitates quality control, and supports modular supply from vendors.

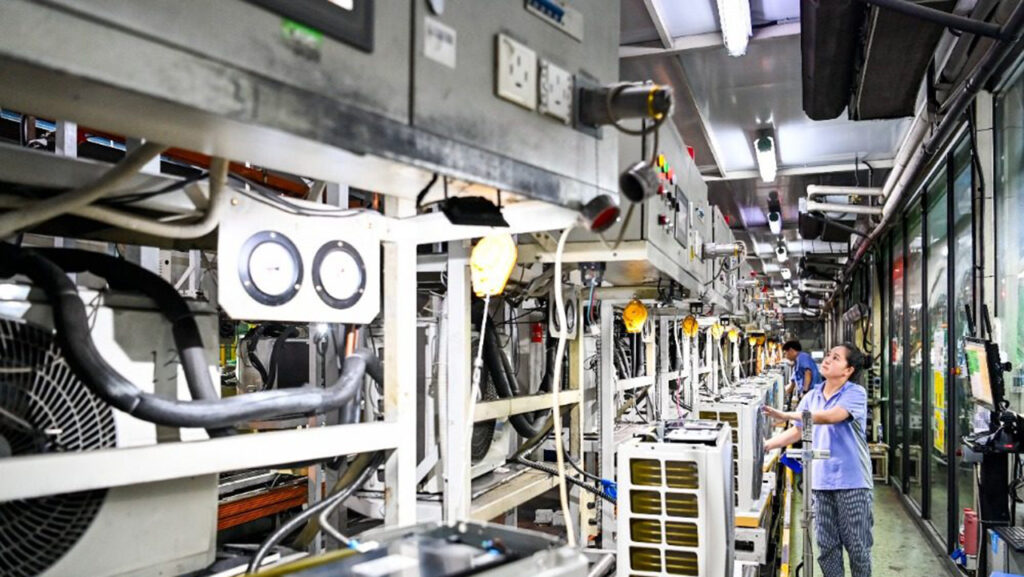

2. Complex In-Line Testing and Performance Validation System

Air conditioners are “semi-finished products”; their final performance must be fully verified before leaving the factory through simulated testing.

In-Line Functional Checks: Stations include electrical safety tests (dielectric strength, ground resistance) and power-on functional checks.

Final Performance Testing (Top Priority): This is the core link in AC production. Assembled units enter dedicated **performance test chambers** to operate under simulated real-world conditions. Computers automatically detect and judge whether all key parameters (cooling/heating capacity, energy efficiency, current, pressure, noise, vibration, etc.) meet standards. This is the final defense line ensuring user experience.

3. High Flexibility and Scalability

Market demand changes rapidly, with numerous product models.

Mixed-Model Production: Assembly lines must be flexible enough to quickly switch between producing different models and capacities (e.g., 1HP, 1.5HP) with minimal or no downtime.

Scalable Design: Line layout and control systems need interfaces reserved for future capacity expansion or technology upgrades to adapt to increased production or process improvements.

4. Fully Traceable, Informatized Process Data

Enables meticulous management through a Manufacturing Execution System (MES).

Unique Code per Unit: Each air conditioner has a unique identifier (barcode/RFID).

Key Data Binding: Critical assembly data (torque values, leak test results, refrigerant charge, performance test data) is bound to this identifier and stored in a database.

Value: Achieves full lifecycle quality traceability from core components to the finished product. If market issues arise, the root cause can be pinpointed for precise recalls and improvements.