Air Conditioner Assembly Line Advantages—Air Conditioner Assembly Line Supplier

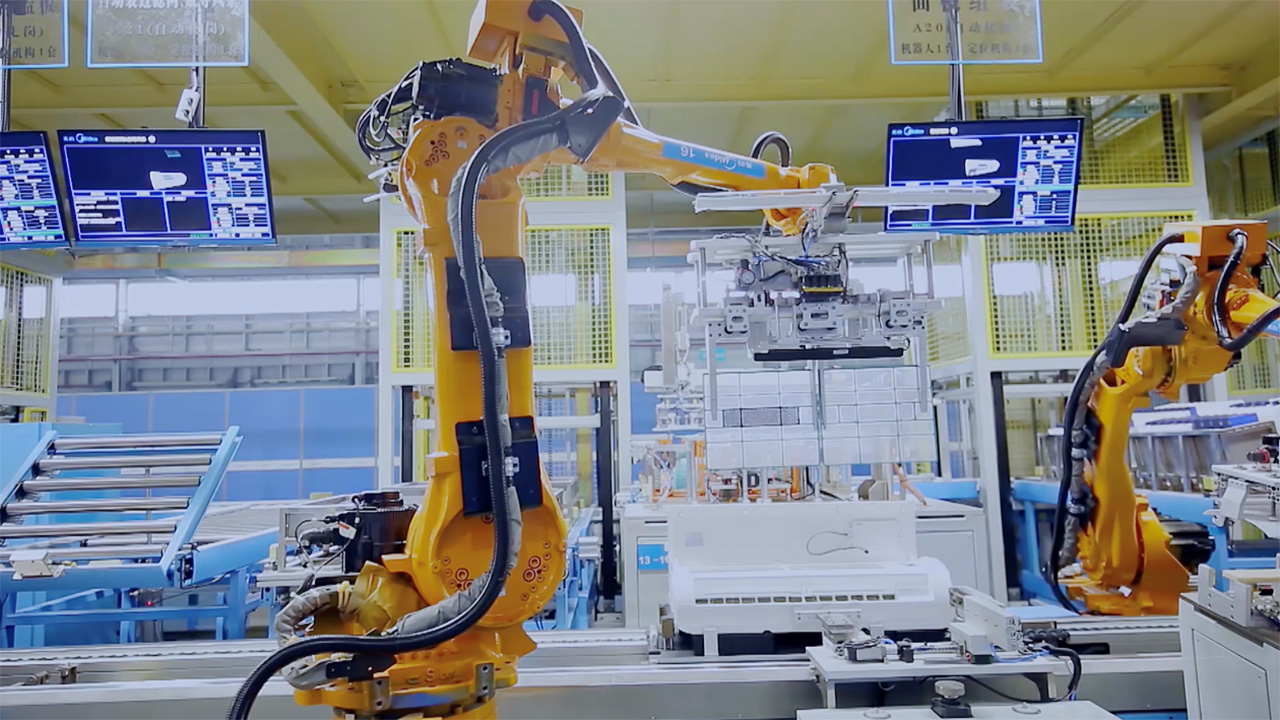

Building automated air-conditioner assembly line not only delivers a leap in capacity and quality, but also creates an extensible platform for future flexibility, digitalization and green manufacturing—the core lever for “smart” upgrading in the home-appliance industry.

Description

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

The advantages of air-conditioner assembly lines—especially automated and intelligent ones—have been fully validated and can be summarized in eight dimensions:

1. Doubled efficiency

Premium smart lines compress takt time to 7–15 seconds per unit, raising productivity by 50–100 %. During peak season they can run 24-hour.

2. Stable quality with half the defect rate

Robotic arms plus AI vision perform in-line inspection on every unit; each AC passes 600–800 automated tests. Human errors such as missing screws or refrigerant-charge deviations drop sharply, cutting the defect rate by 30–50 %.

3. Lower total cost

Although upfront investment is high, large numbers of handling, brazing and assembly jobs are eliminated, reducing labor expense by 30 %+. Material waste and inventory backlog also fall; the larger the volume, the faster the pay-back.

4. Rapid change-over and mixed-flow production

Modular fixtures and software “recipes” let one line switch seamlessly among 2 000+ models—wall-mounted, floor-standing, VRF indoor units, etc.—realizing order-driven flexible manufacturing.

5. Full-process data traceability

A barcode/RFID “birth certificate” is assigned to every chassis; key parts, process parameters and test results are uploaded to the MES. Quality exceptions can be traced back to station and operator within minutes.

6. Safety & occupational health

Robots take over high-risk tasks—high-temp brazing, refrigerant charging, heavy-compressor handling—cutting on-site injuries and reducing dust/VOC emissions, making it easier to meet green-factory standards.

7. Smaller footprint & optimized logistics

Overhead EMS loops and AGV/RGVs deliver parts directly to workstations, eliminating most forklifts and buffer areas. For the same output, floor space can be reduced by 15–20 %.

8. Sustainability & upgrade headroom

Digital twins, AI predictive maintenance and energy-management systems can be layered on later. With falling robot prices and 5G industrial networks, the line’s lifecycle exceeds 10 years, protecting the initial investment.