How to use production lines to increase the production capacity of ATVs (All-Terrain Vehicles)—ATV Production Line Factory

This is a very practical and important issue in manufacturing. Shifting to a production line approach to boost ATV output represents a transition from “workshop-style” or “batch-style” production to modernized, large-scale manufacturing.

The core idea is: Break down the assembly process of the ATV into a series of simple, standardized steps, allowing the product and workers to operate at a fixed cycle time, thereby achieving high efficiency, consistent quality, and predictable output.

Foundational Analysis & Design (Planning Phase)

Planning must come before purchasing any equipment.

- Value Stream Mapping:

- Map the entire current process from raw materials to delivery of the finished product to the customer.

- Identify all value-added and non-value-added activities (e.g., waiting, transportation, rework).

- The goal is to eliminate waste and provide a basis for designing the production line.

- Process Breakdown & Standardization:

- Decompose the final assembly of the ATV into the smallest, actionable steps.

- Create Standardized Work Instructions for each step, specifying tools, torque, methods, and time.

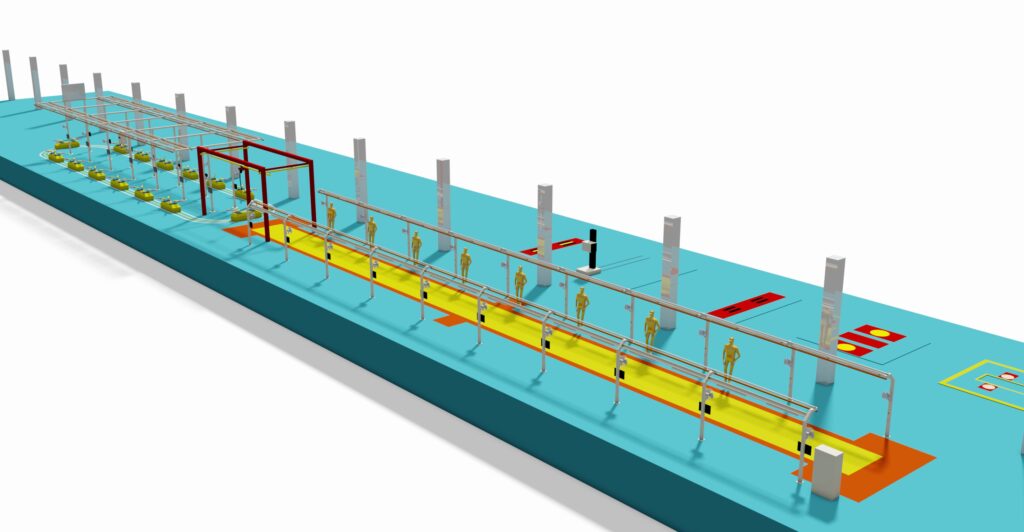

- Production Line Layout Design:

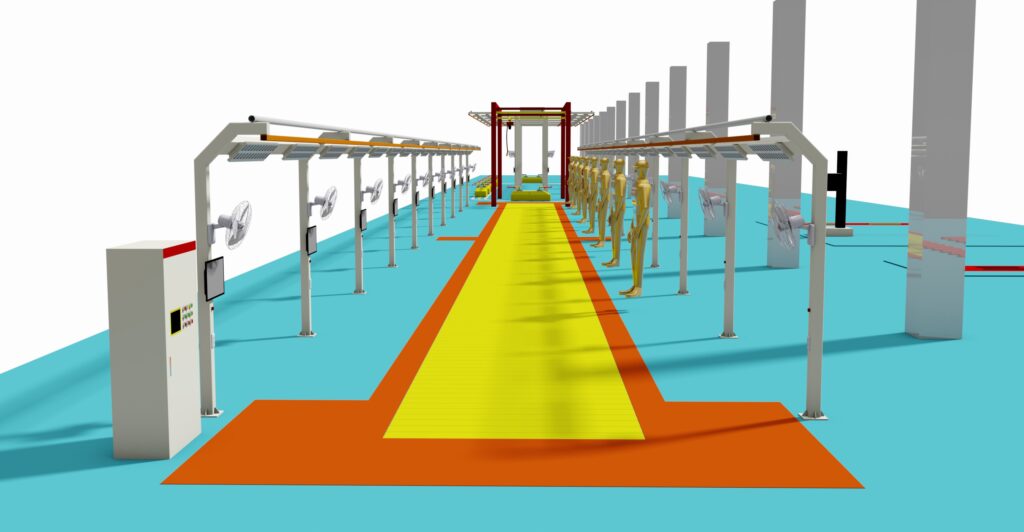

- Assembly Line/Conveyor Mode: The classic approach. Frames are placed on moving pallets and flow past each workstation at a fixed cycle time. Workers remain at their stations to complete their specific tasks.

- Cellular Manufacturing Mode: Group related processes into a “cell,” where one or multi-skilled workers complete a large segment of assembly (e.g., the entire powertrain unit) within one area.

- Recommendation: For a complex product like an ATV, a hybrid model is often used—a main assembly line with conveyor, while some complex sub-assemblies (e.g., engine pre-assembly) are handled in manufacturing cells.

- Determine Takt Time:

- Takt Time = Net Available Work Time per Day / Customer Demand per Day.

- Example: Work 8 hours per day (28,800 seconds), customer demand is 80 vehicles per day, then Takt Time = 28,800 / 80 = 360 seconds/vehicle.

- All aspects of the line design must revolve around this takt time, aiming to make the work time at each station as close as possible to 360 seconds.

Line Hardware & Technical Support (Implementation Phase)

- Main Line Equipment:

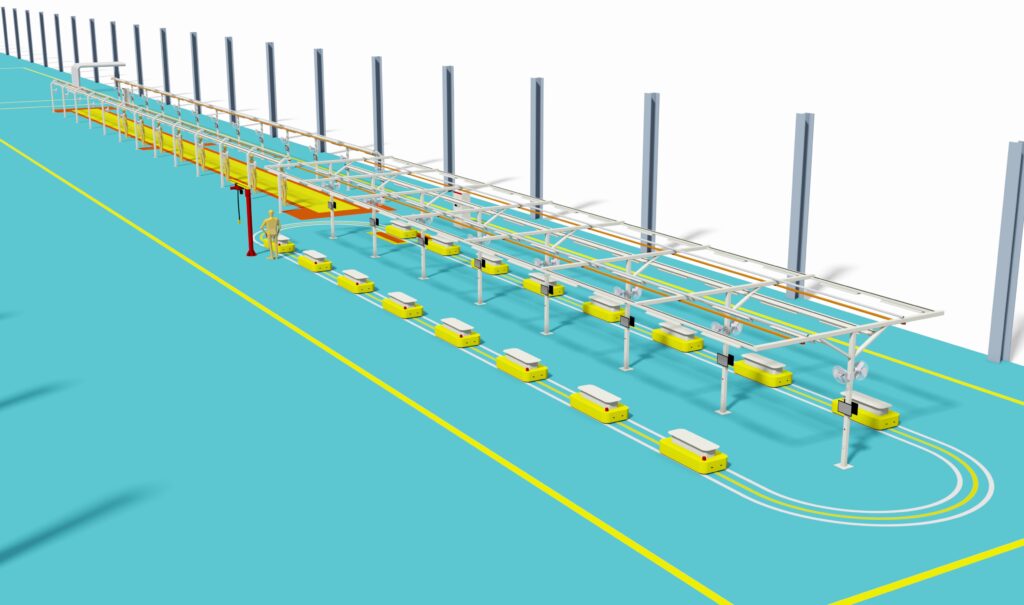

- Conveyor System: Choose drag chains, roller conveyors, slat conveyors, etc., considering the weight and size of the ATV.

- Assembly Pallets/Fixtures: Custom-designed to securely hold the frame and potentially integrate small tools and part bins.

- Material Supply System:

- This is key to increasing capacity! Bottlenecks often occur in material handling.

- Supermarket & Kanban: Set up a “supermarket” near the line to hold a small stock of standard parts. Material handlers replenish based on consumed Kanban cards.

- Sequenced Supply: For large, sequence-specific components (e.g., engines, colored body panels), the logistics department delivers them directly to the corresponding workstation in the production sequence.

- AGV/Tugger Train Delivery: Use Automated Guided Vehicles or tugger trains to deliver materials from the warehouse to the line-side on a timed, quantitative basis, reducing waste from manual handling.

- Tools & Fixtures:

- Electric Torque Tools: Use torque wrenches for critical connections (e.g., wheels, suspension) to ensure consistent quality and record data for traceability.

- Lifting Equipment: Install balancers or small cranes for heavy items like engines and wheels to reduce worker fatigue and improve safety and efficiency.

- Custom Fixtures/Jigs: Design specialized jigs to help workers position components quickly and accurately.

Management & Software Systems (Optimization Phase)

- Personnel Management & Training:

- Cross-Training: Train workers to handle multiple stations for flexible deployment to address bottlenecks and absences.

- Incentive Systems: Establish performance evaluation systems linked to output and quality.

- Team Building: Promote autonomous management, encouraging workers to identify and solve on-site problems (e.g., using an Andon system).

- Manufacturing Execution System (MES):

- This is the “brain” of the production line. An MES can:

- Track Production Progress: Show the real-time status of each vehicle and its location on the line.

- Guide Operations: Equip each station with a screen displaying assembly instructions and special requirements for that specific vehicle.

- Quality Control: Record torque data and inspection results for key processes, enabling full traceability.

- Material Calling: Workers can call for materials with one click via the system, enabling precise delivery.

- This is the “brain” of the production line. An MES can:

- Culture of Continuous Improvement:

- Daily Stand-up Meetings: Hold brief meetings at the start of each shift to review the previous day’s output and quality issues, and set tasks for the day.

- Line Balancing: Regularly measure task times at each station and use ECRS (Eliminate, Combine, Rearrange, Simplify) to rebalance the process and eliminate bottlenecks.

- 5S & Visual Management: Maintain a clean and orderly work environment, making abnormalities (e.g., missing tools, wrong parts) immediately obvious.