How to Choose the Right/Suitable ATV Production Line?—SKD ATV(All-Terrain Vehicles) Production Line

This is a complex decision-making process that requires comprehensive consideration of multiple factors.

Here is a systematic decision-making framework to help you select the most suitable ATV production line:

Step 1: Define Your Positioning and Strategic Goals (Strategic Level)

This is the cornerstone of all decisions. You must first answer the following core questions:

- What is your market positioning?

- Premium Brand: Pursuing high performance, advanced technology, and unique design? Or

- Value Brand: Focusing on economy, practicality, reliability, and affordability?

- Niche Market Specialist: Concentrating on specific areas like youth ATVs, racing models, electric ATVs, or special-purpose vehicles (e.g., for firefighting, patrol)?

- What is your target production capacity?

- Low Volume / Pilot Production: Hundreds of units per year, for market testing or customized production.

- Medium Scale: Thousands of units per year, to meet regional market demand.

- Mass Production: Tens of thousands of units or more per year, targeting the global market.

- What is your budget range?

- This determines whether you opt for a new, high-end automated line, a refurbished second-hand line, or a semi-automated line.

Step 2: Evaluate Production Line Types and Technical Solutions (Technical Level)

Based on the positioning from Step 1, evaluate different production line solutions:

1. Line Scale and Level of Automation:

- Fully Automated Production Line:

- Suitable for: Mass production, pursuit of ultimate efficiency and consistency, manufacturers with ample budgets.

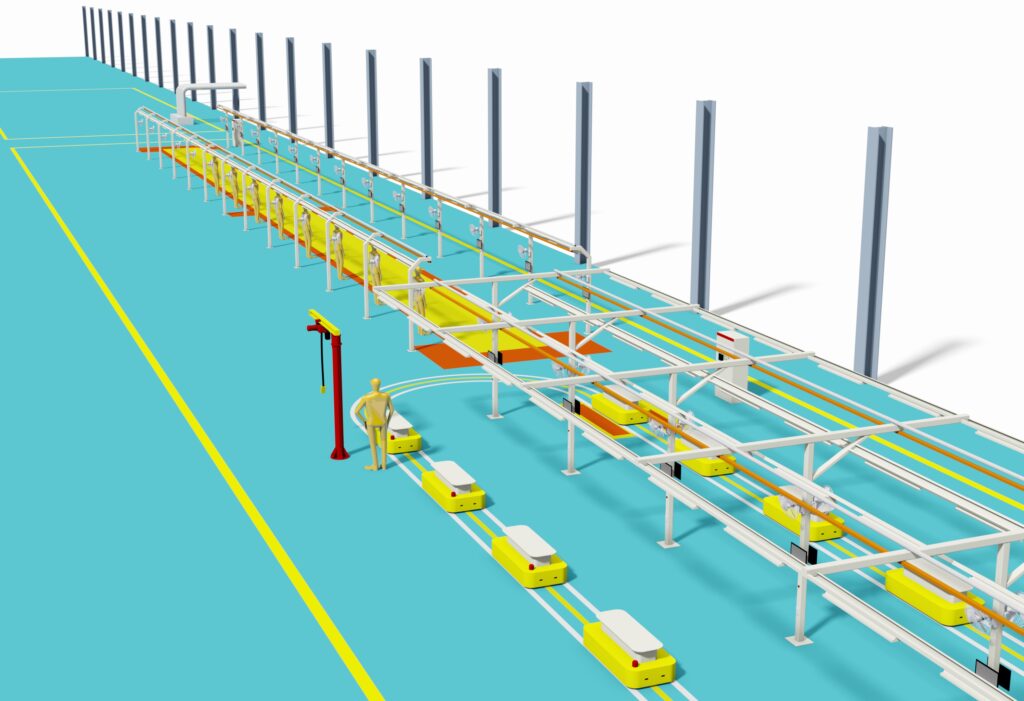

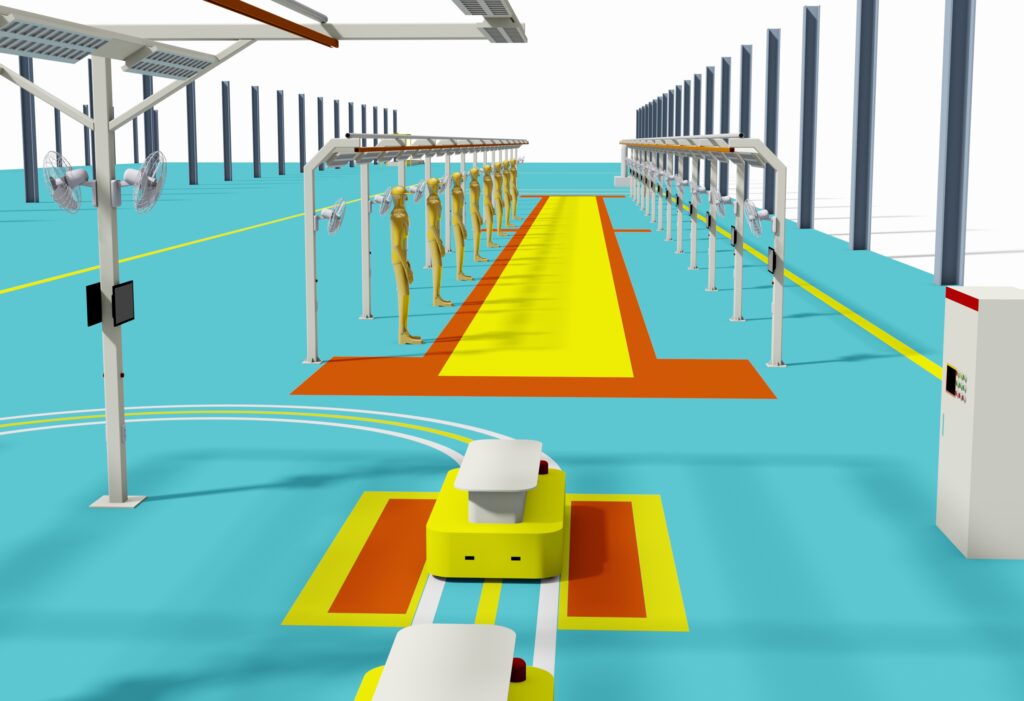

- Characteristics: Extensive use of industrial robots (for welding, painting, assembly), automated conveyor systems, AGVs. Requires huge investment but offers the highest production efficiency and low labor costs.

- Semi-Automated Production Line:

- Suitable for: The preferred choice for most small and medium-sized manufacturers, balancing efficiency and flexibility.

- Characteristics: Automation at key stations (e.g., frame welding, painting), with manual labor for other assembly stations. Moderate investment and good flexibility.

- Modular / Cellular Production Line:

- Suitable for: Low-volume, high-mix, and high-customization production models.

- Characteristics: Production is broken down into independent “cells,” easy to adjust and reconfigure, capable of producing different models simultaneously. Relatively flexible investment.

2. Core Process Equipment Selection:

- Frame Manufacturing:

- Robotic Welding vs. Manual Welding: Robotic welding offers better consistency, suitable for standard models. Manual welding is more flexible for complex or low-volume frames. Your positioning dictates the choice.

- Painting Line:

- This is one of the key investments. Requires a complete pre-treatment (degreasing, phosphating), painting (primer, topcoat), and curing system. Eco-friendly painting (powder coating, water-based paint) is the future trend but comes at a higher cost.

- Powertrain Assembly:

- The marriage line for the engine/motor and transmission requires high-precision tools and positioning equipment.

- Final Assembly Line:

- Drag Chain vs. Skid Chain vs. AGV Smart Logistics: Drag chains are most common; AGVs offer the highest flexibility, enabling “station-to-vehicle” smart assembly, but with higher cost and complexity.

Step 3: Consider Key Support Systems (Support Level)

A production line is more than just hardware:

- Quality Inspection and Testing System:

- Must plan for online inspection (e.g., torque monitoring, electrical testing) and end-of-line tests (e.g., brake testing, water spray testing, test track). Quality is the lifeline of your brand.

- Supply Chain and Material Management System:

- The production line requires stable material supply. Consider component warehousing and line-side material feeding methods (e.g., Kanban, SPS) to ensure smooth production flow.

- Information and Management System (MES):

- A modern production line requires a Manufacturing Execution System (MES) to monitor production progress, equipment status, and quality data, enabling transparent and digital management.

Step 4: Conduct Due Diligence and Make the Decision (Execution Level)

- Supplier Selection:

- Source Multiple Suppliers: Include specialized non-standard automation integrators and established complete vehicle plant solution providers.

- Review Case Studies: Conduct site visits to review suppliers’ past successful projects, especially production lines for similar products.

- Assess Capabilities: Evaluate their technical team, after-sales service capability, and spare parts support.

- Cost-Benefit Analysis:

- Don’t just look at the initial investment; calculate the total cost of ownership, including: equipment depreciation, energy consumption, maintenance, labor, floor space, etc.

- Calculate the Return on Investment (ROI).

- Scalability and Flexibility:

- Is the chosen production line easy to expand in the future? Can it adapt to product model changes? Leaving room for upgrades is crucial.