TV Assembly Line Factory—Key Components of the Assembly Line

Description

We are a professional manufacture of TV Assembly Line/TV Production Line solutions.

TV Assembly Lines/TV Production Lines are Suitable to Assemble/Produce following Televisions and TVs and so on.

Key Components of the Assembly Line

1. Conveyance System: Belt conveyors, chain conveyors, roller conveyors, etc., responsible for transporting TVs between workstations.

2. Pallets/Fixtures: Carry the TVs, holding them in a fixed orientation on the line for easier assembly.

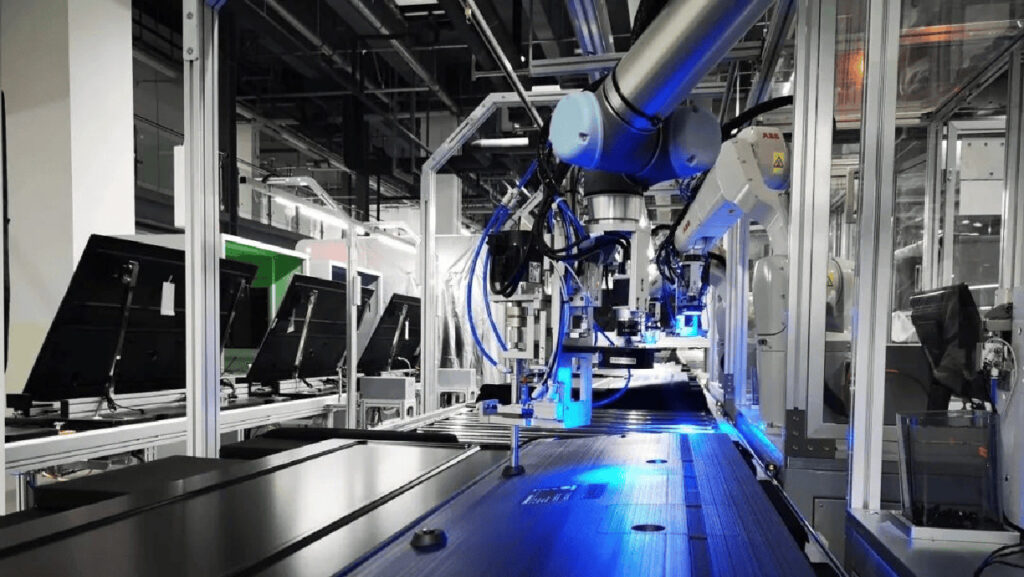

3. Automation Equipment:

Robotic Arms: Used for heavy or high-precision tasks like handling panels, driving screws, applying adhesive.

Automatic Screwdriving Machines: Improve speed and consistency in fastening.

Automatic Marking Machines: Print model numbers, serial numbers, etc.

Machine Vision Systems: Automatically identify component positions, inspect assembly quality, and read barcodes.

4. Testing Systems: Integrated signal generators, audio analyzers, network testers, etc., used for automated testing.

5. Data Collection and Monitoring System (SCADA/MES): Collects production data (e.g., output, cycle time, yield) in real-time, enabling process transparency and traceability.

Modern Development Trends

High Automation and Smart Manufacturing: Industrial robots (including collaborative robots/cobots) are increasingly used, replacing repetitive manual labor in tasks from material handling to precision assembly.

Industrial IoT (IIoT) and Big Data: Sensors at key stations collect data on equipment status, process parameters, and quality. Big data analytics enable predictive maintenance, process optimization, and quality traceability.

Flexible Manufacturing: Assembly lines can be quickly reconfigured for mixed-line production of different sizes and models, meeting demands for diversification and small batch sizes.

Human-Robot Collaboration: Emphasizes synergy between humans and machines in complex assembly or inspection tasks difficult to fully automate, leveraging the strengths of both.

Challenges and Optimization Directions

Challenges:

High Initial Investment: Significant cost for automation equipment and line setup.

Complex Supply Chain Management: Shortage of any single component can halt the entire line.

Rapid Technological Iteration: Constant need for line upgrades and retrofits for new products.

Quality Control Pressure: Screens are fragile components, requiring protection against dust, static electricity, and impact throughout the process.

Optimization Directions:

Lean Production: Eliminating all forms of waste (e.g., waiting, transportation, defects).

Improving Overall Equipment Effectiveness (OEE): Reducing equipment failure and downtime.

Implementing Total Quality Management (TQM): Building quality control into every process step, not relying solely on final inspection.