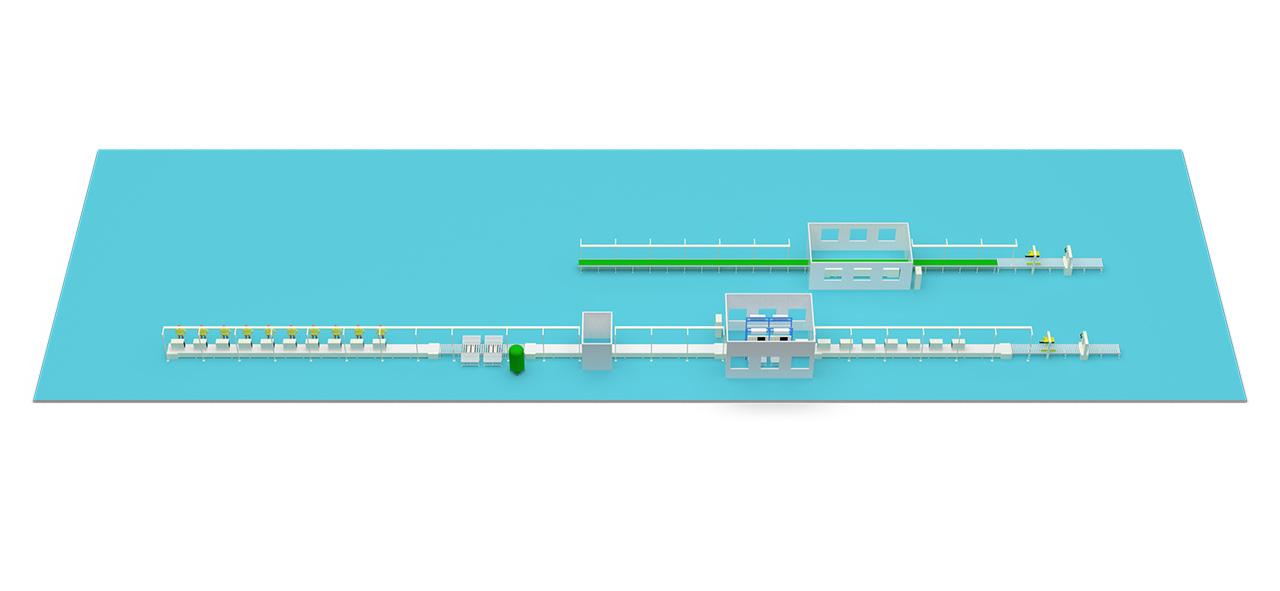

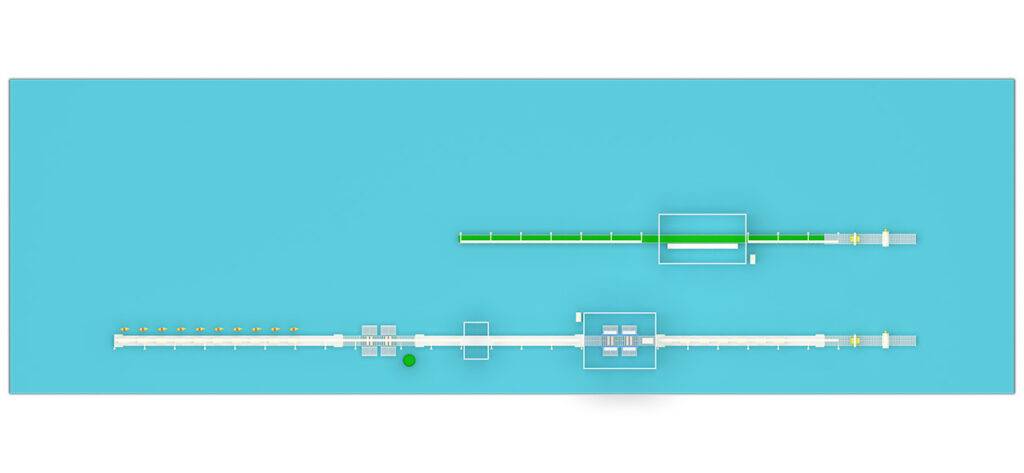

Air Conditioner Assembly Line Design Preparatory Work—Air Conditioner Assembly Line Design and Fabricate

Description

We specialize in providing solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

Air-Conditioner Assembly Line Design Preparatory Work

Phase 1: Preliminary Analysis & Foundational Data Preparation

Before drawing anything, the following analyses must be completed:

1. Product & Capacity Analysis (What to produce? How much to produce?)

Product Families: What types of air conditioners will be produced (e.g., wall-mounted units, cabinet units, indoor/outdoor units for central AC)? What are the differences in their size, weight, and complexity?

Capacity Goals: What are the annual, monthly, and daily production targets? What is the Takt Time? (Takt Time = Available Working Time / Target Output).

Process Routing: Define the Standard Operating Procedure (SOP) for each product type, e.g., Sheet Metal Stamping -> Welding -> Painting -> Two-Core Assembly (Condenser/Evaporator) -> Final Assembly -> Refrigerant Charging -> Testing -> Packaging.

2. Process Analysis (How to produce?)

Process Breakdown: Break down the overall process route into detailed process steps.

Time Measurement: Measure the standard operation time for each step.

Equipment List: List all required production equipment (e.g., punch presses, welders, robots, torque guns, charging stations, leak detectors, performance test chambers) and their dimensions, power requirements, and interface needs.

3. Incorporating Lean Manufacturing Principles

One-Piece Flow: Aim for a continuous flow of single units to reduce Work-In-Progress (WIP) inventory and waiting times.

U-Shaped Cells: For stages like final assembly of indoor/outdoor units, U-shaped lines are common. They reduce operator movement and enable flexible production with fewer workers.

Phase 2: Overall Planning & Layout Type Selection

Based on the preliminary analysis, determine the overall layout strategy. Air conditioner lines are often a hybrid of layout types.

1. Layout Types

Process Layout (Functional Layout): Suitable for initial processes (e.g., grouping all stamping machines together, all welding machines together). Good for low-volume, high-mix production, but material travel distance is long.

Product Layout (Flow Line): Suitable for the final assembly line. Equipment and workstations are arranged in the sequence of assembly operations, forming a continuous line. This is ideal for achieving one-piece flow.

Cellular Layout: Groups multiple machines and operators needed to produce a complete component (e.g., electrical control box, motor-fan assembly) into a “cell.” Highly suitable for sub-assemblies.

2. Logistics Planning (Arteries & Veins)

Material Delivery Paths: Plan routes for delivering materials from the warehouse to line-side storage. Ensure separate paths for material handling vehicles and personnel (people-flow vs. material-flow).

Feeding Methods: Decide whether materials will be replenished using a Kanban (pull) system or scheduled deliveries (SPS). Plan routes and stopping points for AGVs or tuggers.

Waste Handling: Plan the removal path for packaging materials and other waste.