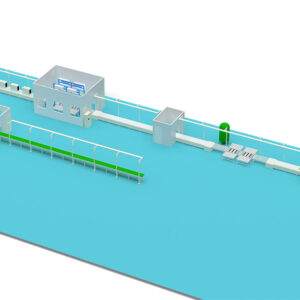

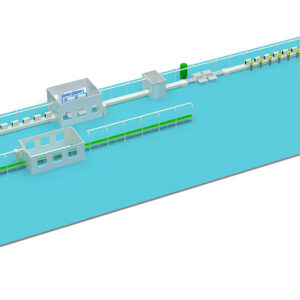

Automated Air Conditioner Assembly Line—Smart Air-Conditioner Assembly Line

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

Automated Air-Conditioner Assembly Line – Introduction

**1. Line Configuration & Key Technologies**

– **Intelligent Conveying**: Accumulation roller or chain conveyor plus AGV feeding; takt time can be adjusted dynamically to support mixed-model production.

– **Robot Cells**: Six-axis robots handle heavy parts like compressors and motors; collaborative robots perform delicate tasks such as wiring, glue dispensing, and foam padding.

– **Automatic Assembly Stations**: Servo presses, automatic screwdrivers, automatic brazing machines, and refrigerant charging modules ensure accurate torque, brazing temperature, and refrigerant dosage.

– **Vision & Sensor Systems**: 2D/3D cameras locate holes, seams, and labels in real time; pressure, flow, and temperature sensors collect performance data for closed-loop control with the PLC.

– **Smart Testing**: Helium or halogen leak detection, full-performance running test (cooling, heating, electrical safety, power) launched with one click; data automatically linked to barcode.

– **IT Platform**: MES downloads orders, recipes, and process parameters; SCADA monitors OEE; digital-twin simulation shortens new-model launch time by over 30 %.

**2. Typical End-to-End Flow**

Automatic material feeding → chassis/housing assembly → robot-mounted compressor → automatic pipe brazing → helium leak test → vacuum & refrigerant charge → automatic PCB locking → blower-motor assembly → visual appearance check → full-performance running test → automatic labeling → bagging & packing → robot palletizing → automatic warehouse entry.

**3. Future Trends**

– **AI inspection**: deep-learning defect recognition gradually replaces manual visual checks, cutting false calls by another order of magnitude.

– **More cobots**: higher man–robot ratio; robots move from fenced areas to shared workstations.

– **Digital twin + edge control**: real-time mirroring of the physical line enables predictive maintenance and reduces downtime by > 20 %.

– **Green manufacturing**: the shift to new refrigerant R290 demands explosion-proof, leak-proof automation, driving safety upgrades for robots and sensors.