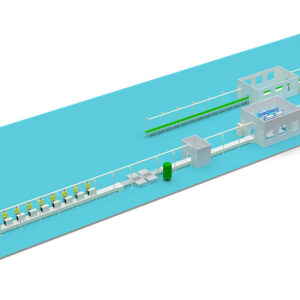

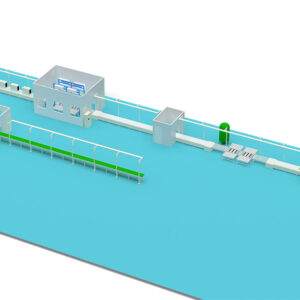

CKD Air Conditioner Assembly Line—Air Conditioner Assembly Line Manufacturer

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

CKD (Completely Knocked Down) air-conditioning assembly lines import or source all parts as loose kits, then carry out final assembly, testing and packing on a local production line. The system is widely used for export-oriented air-conditioner manufacture, especially in countries or regions with high import duties or low labour costs.

Core features

– **Form of supply**: every component—compressor, condenser, evaporator, base pan, piping, electric box, etc.—is packed and shipped as loose parts.

– **Export advantages**: lower tariffs, reduced freight cost, final assembly performed with inexpensive local labour.

– **Suitable products**: split, window, portable, residential and light-commercial air-conditioners.

– **Line types**: roller conveyor, slat conveyor, pallet line, speed-chain line; automatic or semi-automatic.

– **Customisation**: length, speed, colour, structure, control system (PLC + HMI) can all be tailored.

– **After-sales service**: overseas engineers for on-site erection, commissioning, training and spare parts.

Typical applications

– **Export-oriented manufacture**: Chinese factories ship CKD kits to Africa, South-East Asia, South America for local assembly.

– **OEM / ODM partnerships**: customers buy the CKD line, source parts through China’s supply chain, assemble and sell locally.

Main stations (customisable)

– **Pre-assembly**: mount compressor, condenser, weld piping.

– **Vacuum & leak test**: evacuate and check for leaks.

– **Refrigerant charge**: automatic charge of R32 / R410A.

– **Electrical test**: verify PCB, sensors, communication.

– **Performance run**: simulate cooling / heating mode.

– **Final inspection**: cosmetic check, labelling, packing.

Summary

If you plan to **import air-conditioner kits** or **build a plant**, a CKD assembly line is the most cost-effective route. It avoids high import duties, leverages local labour for high-quality assembly.