Air Conditioner Assembly Line design—Air Conditioner Assembly Line Design Factory

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

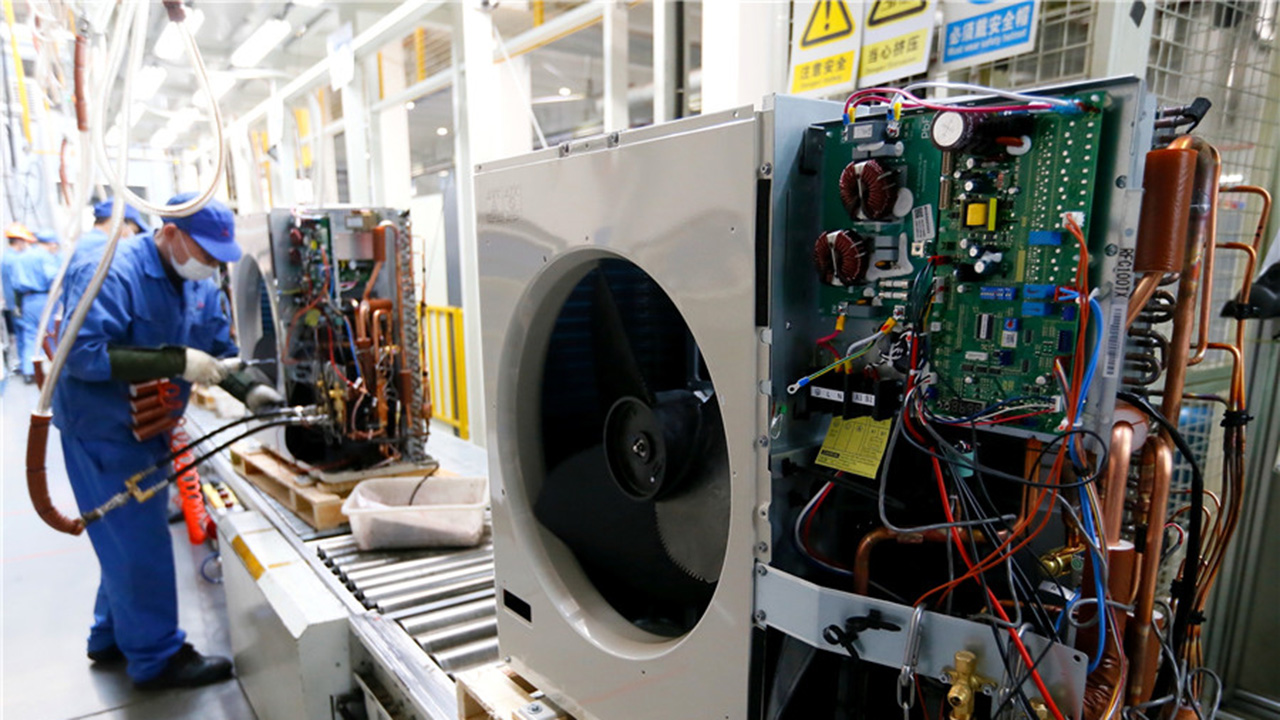

Air-Conditioner Assembly Line Design

1. Design concept

Start with high takt, high flexibility, zero rework. Select conveyor type by cabinet size, then set station pitch and buffer. A U-shaped one-piece flow is preferred to reduce handling distance and floor space. Make the three bottlenecks—vacuum pump-down, helium leak test, and final performance test—into independent modules so capacity or model mix can be changed later without touching the whole line.

2. Conveyor types(As Chinese Customer average for your reference)

– Single-layer speed-chain: 1-3 HP light-commercial units, 25-40 s takt, easy maintenance.

– Over-under speed-chain: 5-10 HP cabinets, 35-55 s takt, built-in elevator saves return loop space.

– Slat chain: 10 HP and above, 45-70 s takt, handles 120 °C drying tunnel.

– Roller pallets + AGV return: low-volume high-mix, flexible takt, linked to MES, supports batch-size-one.

3. Station layout (example: 3 HP outdoor unit, 35 s takt)

Pre-assembly: compressor damper → compressor → 4-way valve block → condenser → fan motor → electric box.

Vacuum block: evacuate → helium leak test → refrigerant charge → quick-coupler removal, ≤ 20 Pa, parallel double-chamber vacuum tank decoupled from main line.

Final test: electrical, run, noise, safety, label, pack.

Buffers: 30 pcs before and after vacuum to absorb minor stoppages.

4. Load & structure(As Chinese Customer average for your reference)

Cabinet 120 kg + pallet 25 kg, dynamic factor 1.3 → 190 kg per station; 20A-2 speed chain, 31 kN break load, safety factor 8.

Slat chain 4 mm thick, 38 mm high, 100 mm pitch, 250 kg/m allowable; 1.5 kW double-shaft motor verified by torque calculation.

5. Customization(As Chinese Customer average for your reference)

Quick change: pallet with quick-fit clamps, model change in ≤ 5 min; robot stations have 150 mm adjustable feet for 1-5 HP height range.

Multi-language labels: on-line print-apply machine supports Chinese, English, Spanish templates selected on HMI—no hardware change.