Air Conditioner Assembly Line Types—Air Conditioner Assembly Line Design and Manufacture

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

Types of Air Conditioner Assembly Lines

Air conditioner assembly lines can be classified from several perspectives. The following is a systematic summary:

A. By Product Type

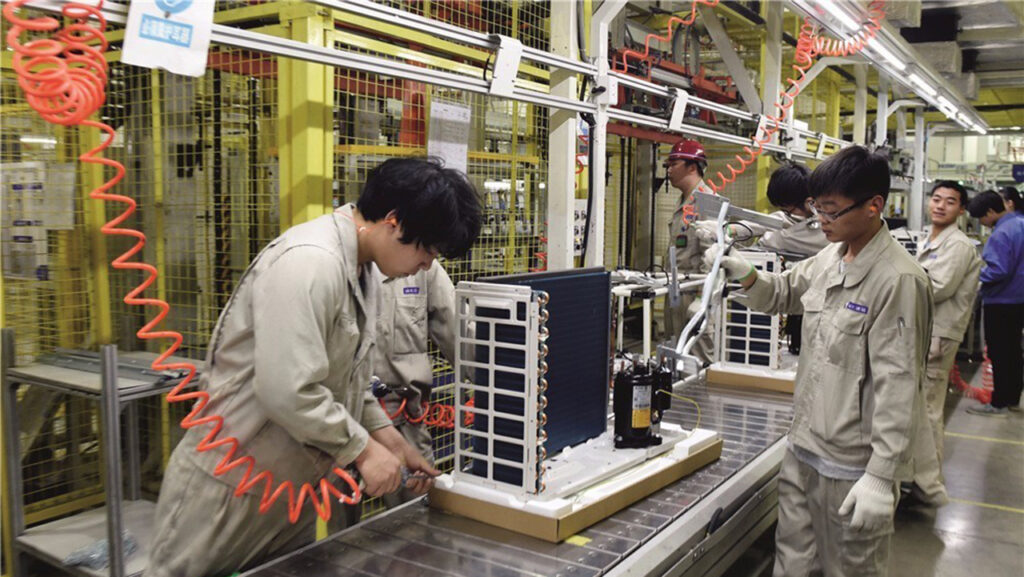

1. **Residential A/C Assembly Line**

– Includes **indoor-unit line** and **outdoor-unit line**, handling fans, electric controls, evaporators, compressors, condensers, etc.

2. **Commercial / Industrial A/C Assembly Line**

– For large units such as central air-conditioners or heat-pump chillers; usually more complex and longer.

B. By Automation Level

1. **Semi-automatic Line**

– Combines manual work with automatic equipment; suitable for small-to-medium batch production.

2. **Fully-automatic Line**

– Uses PLC control, robots, automatic testing, etc.; ideal for high-volume, standardized production.

C. By Conveying Method

1. **Chain Conveyor Line**

– Simple structure, heavy load capacity; good for heavy parts.

2. **Roller Conveyor Line**

– Smooth, low-noise transport for medium-weight products.

3. **Belt / Slat Conveyor Line**

– For light-duty assembly, often used for electronic sub-assemblies or small components.

4. **Overhead (Power-and-Free) Conveyor Line**

– Saves floor space; suitable for long processes with many stations.

D. By Assembly Stage

1. **Sub-assembly Line**

– Independent lines for compressors, heat exchangers, electric control boxes, etc.

2. **Main Assembly Line**

– Integrates all sub-assemblies into the complete unit—fastening, wiring, piping, etc.

3. **Testing & Burn-in Line**

– Vacuum pumping, refrigerant charging, electrical safety tests, running-in (burn-in) tests.

4. **Packaging Line**

– Automatic bagging, boxing, sealing, labeling.

E. By Production Organization

1. **SKD / CKD Assembly Line**

– For export or overseas plants; uses semi-knocked-down or completely-knocked-down kits.

2. **Modular Assembly Line**

– Each functional module is independently adjustable, easy to expand and maintain.