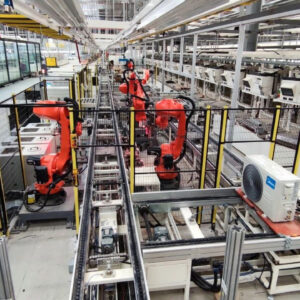

Air Conditioner Assembly Line Maintenance—SKD Air Conditioner Assembly Line

Description

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

Assembly Line Maintenance for reference

1. Daily 10-minute routine

– Check electric/pneumatic screwdrivers: torque-test 5 pcs; if error > ±3 % change the bit and re-torque immediately.

– Visual belt check: deviation smaller than one finger width (≤ 5 mm); rollers must turn by hand, no abnormal noise.

– Fixture locating pin: shake test—no play, no visible wear; if loose circle with blue marker and call maintenance.

– Hit each e-stop, pull-cord and light curtain once; line must stop within 0.5 s and reset normally.

– 5S: bench top free of screws, dust and oil; waste bin < 2/3 full.

2. Weekly 30-minute routine

– Chain sag: press middle with finger; deflection less than one link height (≈ 2 % of centre distance). Re-tension if needed.

– Press cylinder gauge: run 3 idle cycles; pointer fluctuation ≤ 0.02 MPa. After de-pressurising top up hydraulic oil to 1/2 sight glass.

– Wipe sensor face with alcohol; block beam twice—PLC input lamp must flash instantly; re-seat connector until “click” is heard.

– Anti-loosen paint line on bolts: if red paint is mis-aligned, re-torque to standard value and paint a new line.

3. Monthly 2-hour routine

– Remove electric screwdrivers to bench tester; 5-point torque curve must lie within ±3 % band. Stick green “monthly OK” label.

– Run reference program on servo slide; laser interferometer repeatability ≤ 0.05 mm. If exceeded, compensate backlash, then replace support bearing if necessary.

– Apply EP2 lithium grease to whole twin-speed chain until fresh grease squeezes out; measure chain link wear with callipers—replace section if wear > 1.5 %.

– Sweep test rod slowly through light curtain at 30 cm; if any beam fails, replace emitter/receiver module and file report.

4. Quarterly one-shift (8-hour) routine

– Major press-cylinder service: change all seals, filter screen and pressure-sensor O-rings; run 20 cycles—no leakage.

– Belt line: release tension—remove belt—grease all roller bearings—level frames (spirit level 0.5 mm/m)—re-install belt—set tension with gauge.

– Force every I/O on/off; PLC must show no drops. Back up program and burn to CD with quarterly label.

– Calibrate critical displacement, pressure and leak testers; issue third-party or in-house certificate valid for one year.

5. Annual shutdown week

– Repaint whole line; re-number all trunking and cables; replace any aged cables or air hoses.

– Check servo-motor insulation, earthing and encoder battery (3.6 V); change battery if voltage < 3.3 V.

– Full spare-part stock-take: photograph “zero-stock” items with red tag; purchasing must refill within 7 days.

– Update manual revision number; organise training exam.