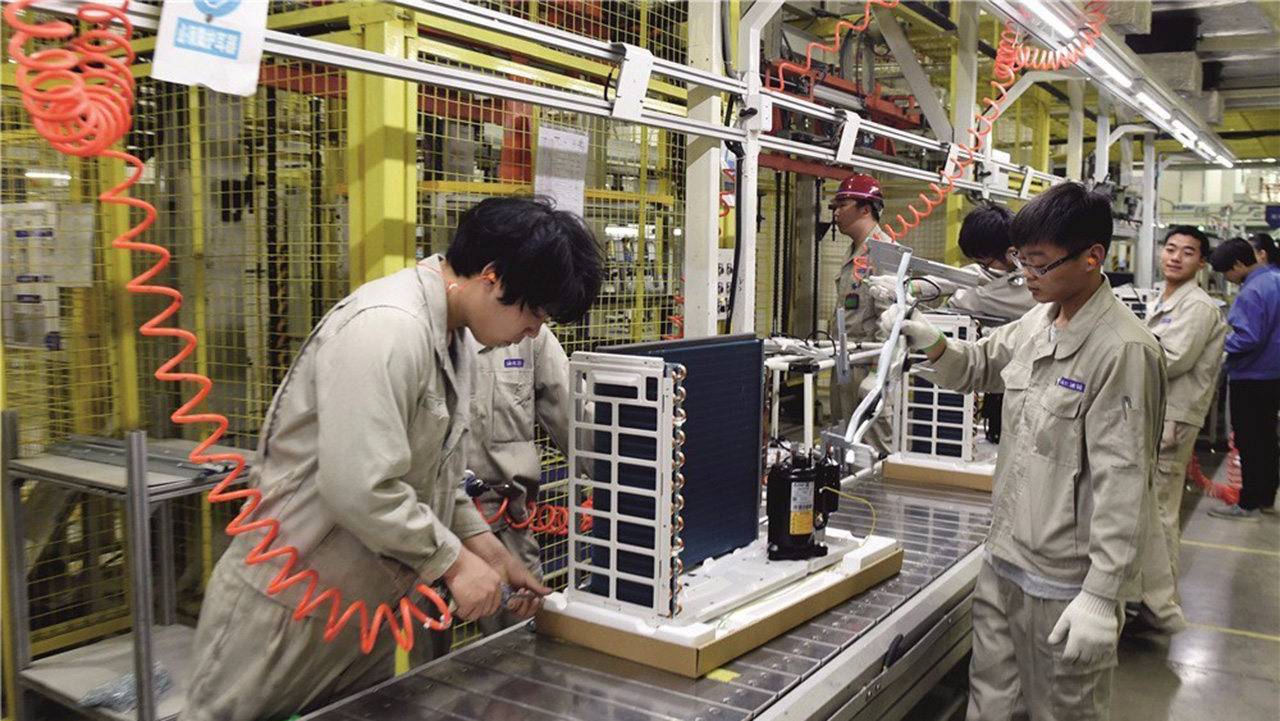

Air Conditioner Assembly Line Characters—Household Air Conditioner Assembly Line

Modern air-conditioner assembly lines center on “high automation + high flexibility + digital quality control,” balancing efficiency, cost, environmental impact and safety to meet the home-appliance industry’s demands for large volume, high variety and rapid product iteration.

Description

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

-

High automation with minimal labor

From sheet-metal stamping, plastic injection and heat-exchanger fabrication to final assembly, leak testing and packaging, robots, automatic screwdrivers, auto-brazing machines and refrigerant-charging stations are deployed throughout. Operators only load/unload parts and perform patrol inspections, sharply cutting labor cost and improving consistency.

-

Modular, flexible design

Quick-change fixture pallets, interchangeable programs and standardized mechanical interfaces allow multi-model, multi-spec indoor/outdoor units to be mixed on the same line, supporting small-batch, high-variety production and future capacity expansion. -

High takt time and throughput

Continuous slat or roller conveyors with parallel stations deliver 24-hour capacities of 500+ sets per line. One-piece flow, bottleneck balancing and MES-based dynamic scheduling further shorten takt. -

In-line quality control along the full process

Critical stations integrate leak detection, vacuum monitoring, electrical-safety tests, performance testing and machine-vision cosmetic inspection. Data are uploaded to MES in real time, enabling automatic reject diverting and full traceability.

-

Digital and intelligent management

MES/SCADA systems collect and analyze orders, materials, equipment status and process parameters on the fly. AR glasses and digital dashboards guide operators and prevent errors. Seamless interface with ERP/WMS forms a closed-loop smart factory. -

Compact footprint and efficient logistics

Vertical buffers, overhead pallet return loops and AGV-based material supply minimize floor-level handling. Line layouts (O, U or L shape) make full use of plant height and floor space. -

Green manufacturing and low energy consumption

Phosphorus-free silane pretreatment, low-slag spraying, energy-saving servo presses, inverter vacuum pumps and refrigerant-recovery technology reduce both energy use and emissions. -

Safety and ergonomics

Enclosed guards, safety light curtains, interlocked doors and collaborative robots lower injury risks. Noise extraction, fume removal and ESD protection are fully integrated.

For further and suitable Assembly Lines/Production Lines design and quotation, please first contact us to confirm the three key parameters—**production capacity (takt time), site dimensions, and budget range**.