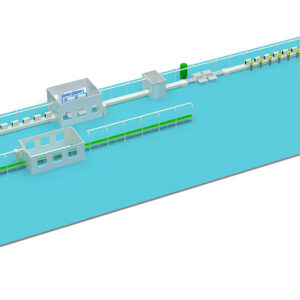

Air Conditioner Assembly Line—Air Conditioner Assembly Line Factory

A/C assembly line: parts QC → mount base & compressor → coil pipe, weld, leak test → install fan & motor → wire control box → evacuate & charge refrigerant → performance & safety test → aging → auto pack & store.

Description

We specialize in providing comprehensive solutions for Air Conditioners Assembly Lines/Production Lines.

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

Air-conditioning Assembly Line Specification

An air-conditioning assembly line is a highly automated, multi-process manufacturing system that covers from parts pre-treatment to finished-goods packaging. The key stages and technologies are outlined below.

1. Parts Pre-treatment

– Incoming inspection of compressors, condensers, evaporators, etc.

– De-dusting, drying, initial electrical checks.

2. Mechanical & Electrical Assembly

Outdoor unit

– Mount compressor and condenser.

– Laser-braze copper pipes.

– Vacuum.

– Charge refrigerant.

Indoor unit

– Install evaporator and cross-flow fan.

– Assemble air duct & guide vane.

– Plug in control board and sensors.

3. Hermeticity Check

Helium mass-spectrometer leak test.

4. Full-performance Test

Functional

Functional

– Switch cooling/heating; set-point accuracy.

Reliability

– Run 100 h at –10 °C ~ 43 °C; energy-efficiency decay ≤ 3 %.

5. Packing & Traceability

Auto-scan serial number, upload refrigerant type and test data.

AGV transfer to warehouse; carton crush strength ≥ 8 000 N.

For further and suitable Assembly Lines/Production Lines design and quotation, please first contact us to confirm the three key parameters—**production capacity (takt time), site dimensions, and budget range**.