How to Use Production Lines to Improve ATV Production Efficiency—ATV Production Line Design

Improving the production efficiency of All-Terrain Vehicles (ATVs) by introducing and optimizing production lines is a systematic project involving the coordinated improvement of multiple aspects such as layout, processes, personnel, equipment, and supply chain.

Here is a detailed, step-by-step implementation plan:

Step 1: Basic Analysis and Planning (Diagnosis and Design)

Before making any changes, it is essential to understand the current situation.

- Value Stream Mapping:

- Map the entire current production process information flow from raw materials to finished product shipment.

- Identify all process steps and measure the cycle time, work-in-progress (WIP) inventory, changeover time, and first-pass yield for each step.

- The goal is to identify bottleneck processes and sources of waste (e.g., waiting, transportation, rework, overproduction).

- Production Line Type Selection:

- Traditional Batch Flow: Groups similar machinery together (e.g., welding area, painting area, assembly area). Suitable for low-volume, high-mix production but creates significant WIP and waiting.

- Cellular Manufacturing: Creates a small “production cell” containing all necessary equipment and personnel for a specific model or series of ATVs. This drastically reduces material handling distance and WIP, offering high flexibility.

- Mixed-Model Assembly Line: Allows different ATV models to be produced in any sequence on the same assembly line without requiring changeovers. This is the most efficient method but places high demands on material supply, tooling design, and production planning.

Recommendation: For a product like ATVs, which is relatively complex but has some standardization, a combination of Cellular Manufacturing and Mixed-Model Assembly Lines is recommended. For example, use cells for frame welding and a mixed-model line for final assembly.

Step 2: Production Line Layout and Optimization (Hardware Transformation)

Core principle: Reduce waste and create flow.

- Single-Piece Flow:

- The ideal state is to produce one piece at a time and immediately pass it to the next process. This maximally exposes problems, reduces inventory, and shortens lead times.

- In ATV production, strive to have major components like frames and engines move in a single-piece flow.

- U-Shaped Line Layout:

- Arrange equipment in the sequence of the process in a U-shape.

- Advantages:

- The entrance and exit are on the same side, facilitating material supply and allowing one operator to handle multiple machines.

- Reduces operator movement distance, enabling “multi-process handling” or man-machine collaboration.

- Provides clear visibility, facilitating team communication and collaboration.

- Material Supply Optimization:

- Establish Supermarkets: Set up small warehouses near the production line to store small quantities of high-usage standard parts.

- Implement a Pull System (Kanban): Subsequent processes withdraw the needed amount of materials from previous processes using Kanban (physical or electronic signals) based on consumption. This prevents overproduction.

- Point-of-Use Delivery: Designated material handlers deliver parts directly to the line-side racks according to fixed schedules, routes, items, and quantities.

Step 3: Process and Standardization (Software Upgrade)

- Standardized Work:

- Create detailed, illustrated Standard Work Instructions for each station.

- Content includes: standard time, operational steps, required tools, torque requirements, quality checkpoints, safety precautions, etc.

- This is the foundation for all improvements, ensuring stability in quality and efficiency.

- Quick Changeover (SMED):

- For processes requiring changeovers (e.g., stamping, molding), separate changeover tasks into “internal” (must be done when the machine is stopped) and “external” (can be prepared while the machine is running).

- Convert internal tasks to external and reduce internal time through tool optimization, parallel operations, and functional standardization. The goal is “Single-Minute Exchange of Die”.

- Automation and Smart Technology Application:

- Spot/Arc Welding Robots: For frame welding, ensuring consistent quality and efficiency.

- Automatic Painting Lines: Achieve uniform, efficient, and environmentally friendly painting.

- Automated Fastening Equipment: Use electric torque wrenches with controlled torque and data traceability for critical bolts (e.g., wheels, suspension).

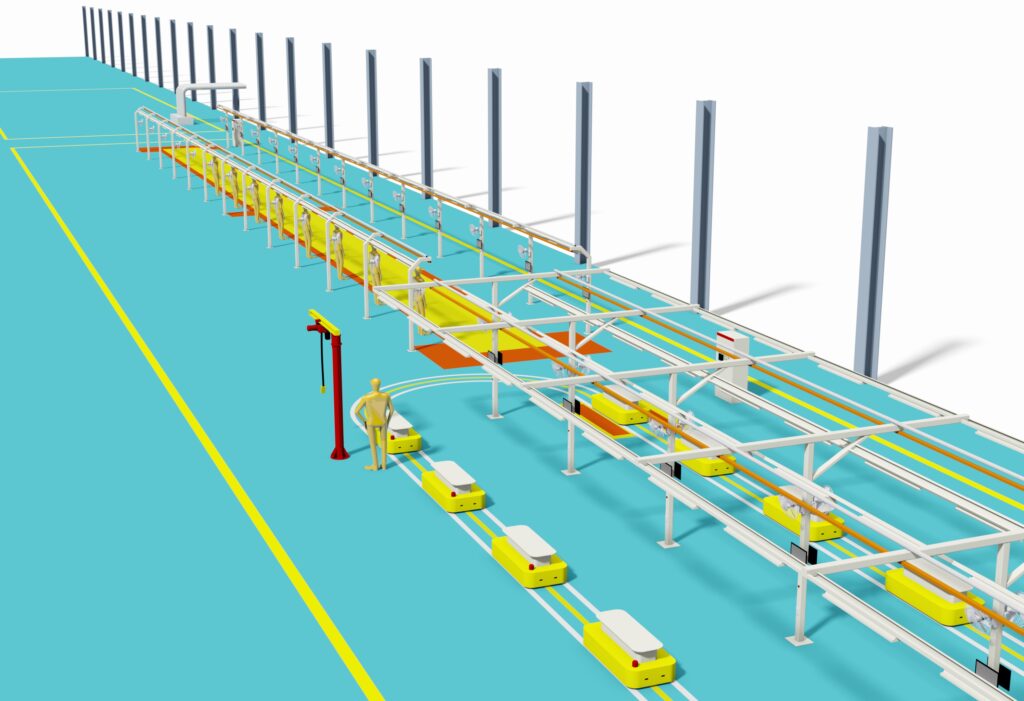

- AGVs/AMRs: For automatically transporting heavy components (e.g., engines, frames) within the workshop.

- Vision Inspection Systems: Automatically check for assembly completeness and part correctness.

Step 4: Personnel Management and Continuous Improvement (Culture Shaping)

- Cross-Training:

- Train employees to handle multiple process steps.

- This allows the production line to flexibly respond to fluctuations in output and absenteeism, and is key to achieving cellular manufacturing and line balancing.

- Implement Lean Tools and Culture:

- 5S Management: Sort, Set in order, Shine, Standardize, Sustain. Create a clean, orderly, and safe working environment—the prerequisite for all improvements.

- Andon System: When quality, equipment, or material problems occur, operators can pull an “Andon” cord or press a button for help, prompting immediate response from management and support staff.

- Continuous Improvement Teams: Encourage employees to form teams to propose improvements for problems they encounter, and provide rewards.

- Data Visualization:

- Set up electronic boards on the production floor to display real-time information on production plans, actual output, line status, quality issues, etc.

- Makes the production status clear to everyone, facilitating quick decision-making.

Step 5: Supply Chain Synchronization

Production efficiency improvements cannot be achieved in isolation.

- Supplier Collaboration:

- Establish long-term partnerships with key suppliers, requiring them to adopt the same JIT (Just-In-Time) model, delivering small batches frequently.

- Share production plans so suppliers can foresee your demand.

- Quality at the Source:

- Communicate quality inspection standards to suppliers and require their incoming material quality to meet standards, even implementing “dock-to-stock” programs to ensure quality from the source.