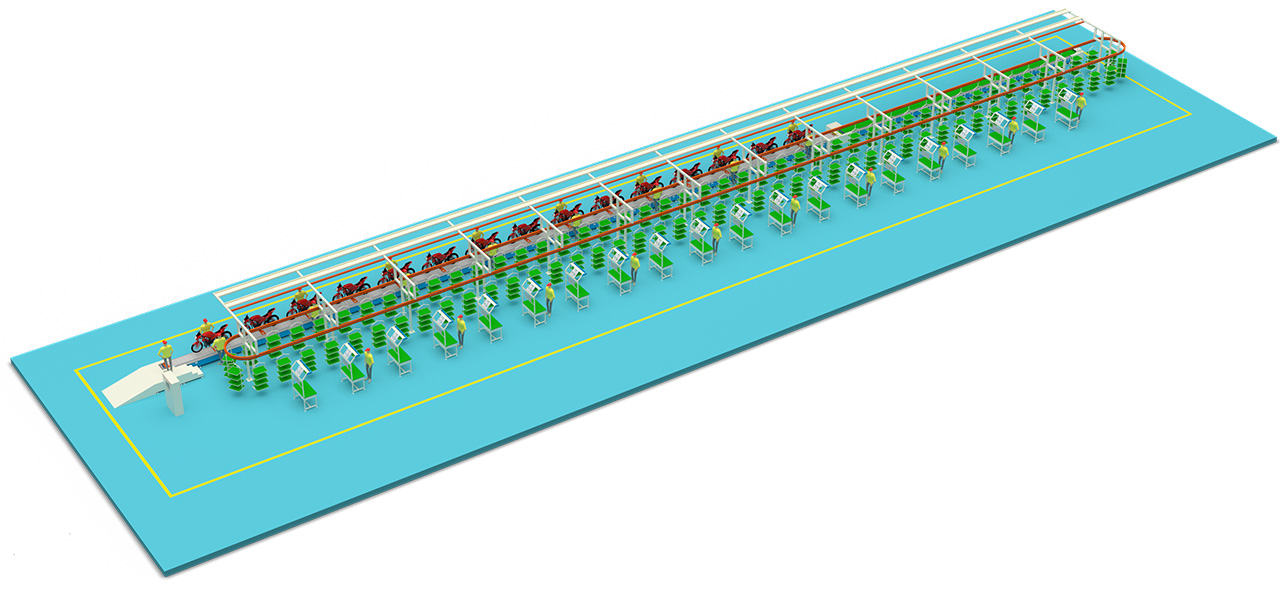

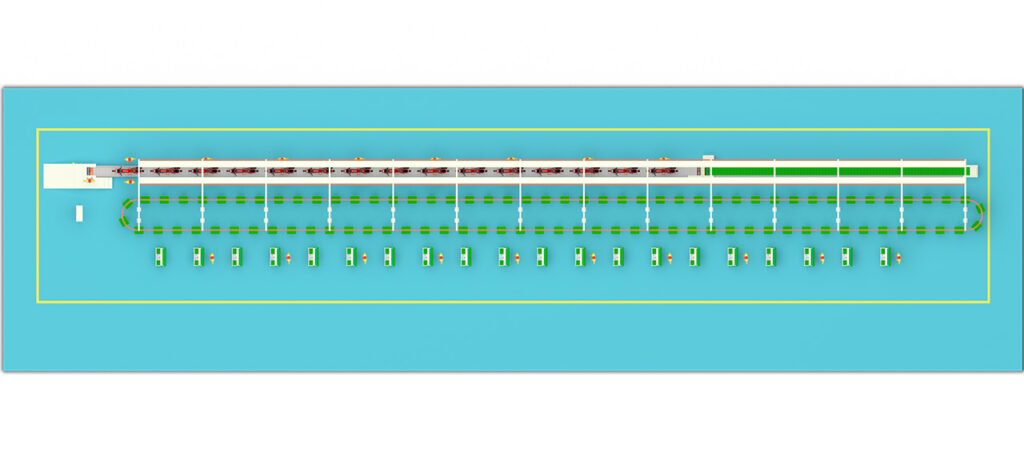

Motorcycle Assembly Line Design— Main Advantages of Motorcycle Assembly Lines

Description

E-bike Assembly Lines are Suitable to Assemble/Produce 2 wheel Motorcycles, 2 wheel Scooters, 2 wheel Electric-cycles, 2 wheel E-Bikes, Bicycles, and so on.

Main Advantages of Motorcycle Assembly Lines

1. Extremely High Production Efficiency and Scalability

Core Advantage: By breaking down the complex assembly process into simple, standardized steps, parallel operations and continuous flow are achieved.

Manifestations:

Production Takt Time: The line operates at a fixed rhythm, with a motorcycle rolling off the line every few minutes.

Specialized Division of Labor: Each worker focuses on only a few operations, leading to very high proficiency and speed.

Mass Production Capability: This enables large-scale, standardized manufacturing, capable of meeting massive global market demand. The widespread availability of modern motorcycles would be unthinkable without assembly lines.

2. Significantly Reduced Production Costs

Core Advantage: Increased efficiency and optimized resource use directly lead to lower cost per unit.

Manifestations:

Optimized Labor Costs: Reduces reliance on highly skilled, all-round technicians, lowering the skill requirements and training costs for individual workers.

Reduced Time Cost: Drastically shorter unit production time means more products can be made in the same period, spreading fixed costs like factory space and equipment.

Less Material Waste: Lean material supply and standardized procedures reduce misassembly, missing parts, and part damage.

3. Excellent and Consistent Product Quality

Core Advantage: Assembly lines minimize quality fluctuations caused by human factors through standardization and process control.

Manifestations:

Standardized Work: Operations, tools, and torque settings are standardized at each station, ensuring identical assembly processes for every vehicle.

In-line Quality Checks: Quality inspections are integrated into each critical station and the final stage (e.g., torque monitoring, Andon systems), allowing immediate problem detection and correction rather than post-assembly rework.

Traceability: Key data (e.g., bolt torque) is recorded, enabling precise tracing of any issues back to specific batches and workstations.

4. High Production Flexibility and Adaptability

Core Advantage: Modern flexible assembly lines can respond quickly to market changes.

Manifestations:

Mixed-Model Production: The same line can simultaneously or quickly switch between producing different models, configurations, or even colors of motorcycles, meeting personalized customization demands.

Rapid Model Changeover: When launching new models, changes can be made by replacing some fixtures and reprogramming robots, significantly shortening the product update cycle.

5. Simplified Production Management and Supply Chain Optimization

Core Advantage: The linear production flow makes management clear and efficient.

Manifestations:

Clear Progress Visibility: Managers can easily see production progress, bottleneck stations, and inventory levels.

Lean Material Supply: Integrates perfectly with “Just-In-Time” production, where parts are delivered precisely according to the production rhythm, greatly reducing inventory costs and space usage.

Easier Planning and Forecasting: Based on a stable production takt time, output and delivery dates can be predicted with high accuracy.

6. Reduced Worker Skill Threshold and Labor Intensity

Core Advantage: Decomposing complex processes significantly reduces the difficulty of individual tasks.

Manifestations:

Shorter Training Cycles: New workers can master the operations of a specific station relatively quickly and start working efficiently.

Distributed Labor Intensity: Robots handle the most strenuous and repetitive tasks (e.g., moving engines, welding), while workers focus more on installation, adjustment, and quality checks requiring flexibility and judgment.