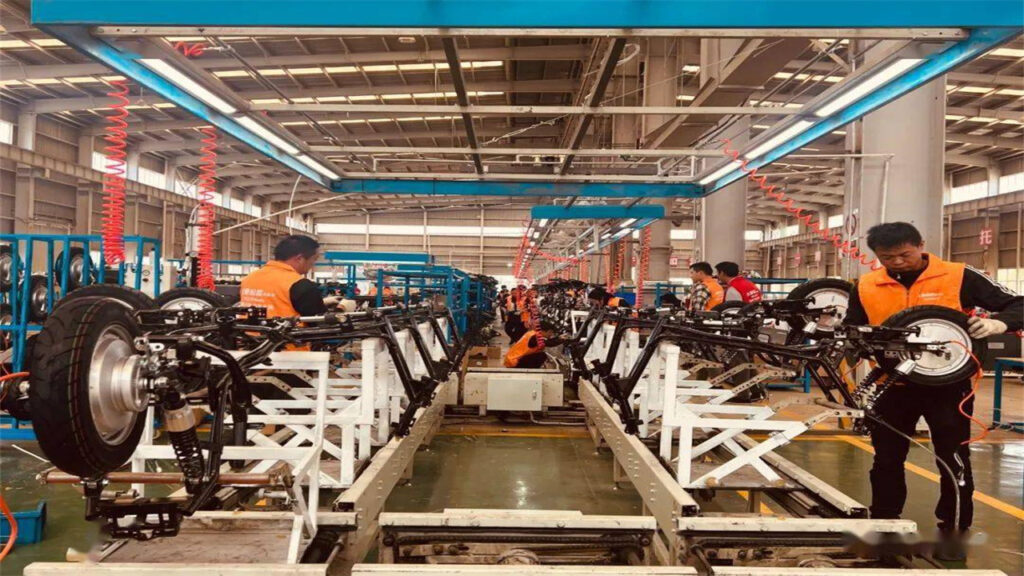

2 Wheel Motorcycle Assembly Line:How to Reduce the Production Costs of Motorcycles by Automation

To reduce the production costs of motorcycles using automation and robotics, consider the following strategies:

- Introduce Advanced Technology:

Implement machine vision systems for component inspection and quality control, utilize machine learning and AI to optimize production processes, and achieve intelligent production line management. - Optimize Production Processes:

Arrange a reliable supply chain for components, optimize production line layout, use intelligent scheduling systems, and efficiently allocate production tasks to improve the utilization of the production line. - Continuous Improvement and Innovation:

Continuously assess and improve the production line, identify and resolve issues, promptly adjust production processes and technologies to enhance the efficiency and quality of the production line. - Develop a Professional Technical Team:

Provide professional training and development opportunities to enable the technical team to possess strong technical capabilities and innovation spirit, promoting continuous technological advancement. - Focus on Quality Control and Management:

Establish a comprehensive quality control system, use appropriate testing equipment and methods, and ensure the quality stability of components and finished products. - Continuous Monitoring and Data Analysis:

Use real-time monitoring of data and indicators from various stages of the production line, employ data analysis tools to quantitatively analyze and optimize suggestions for the production line’s operation. - Establish Good Partnerships:

Maintain solid relationships with suppliers and partners to ensure a stable supply chain and component quality, enhancing the production line’s efficiency and quality. - Adopt Automated Assembly Processes:

Utilize robotic technology and automated equipment, such as automatic screw machines and welding robots, to efficiently complete various assembly tasks, improving production efficiency and consistency. - Precision Manufacturing Processes:

Employ precision processes like CNC machining to ensure the accuracy and quality of components. - Efficient Layout Design:

Optimize the production process to enhance overall production efficiency. - Environmental and Energy Efficiency:

Design and operate with environmental and energy efficiency in mind, using energy-saving machinery and equipment. - Comprehensive Testing and Inspection Processes:

Ensure every vehicle meets the factory standards before leaving the production line. - Flexibility and Adaptability:

Design the production line with flexibility to accommodate different models and configurations of motorcycle production. - Robust Quality Control System:

Implement strict quality control measures at every stage.

By implementing these measures, companies can effectively reduce the production costs of motorcycles while ensuring product quality.